Fraunhofer Research Awards Ceremony 2022

On the evening of May 19, the Fraunhofer-Gesellschaft honored outstanding projects by its researchers at its Annual Meeting in Hamburg. Three Joseph von Fraunhofer Prizes, one “Joint Research” Stifterverband Science Prize and − for the first time at the Fraunhofer Annual Meeting − the Fraunhofer Founder Award were awarded as part of this year’s meeting.

Joseph von Fraunhofer Prizes 2022

Unique measurement technology − 3D-based position control in radiotherapy

New hope in the fight against cancer: A research team at the Fraunhofer Institute for Applied Optics and Precision Engineering IOF has worked closely with Varian Medical Systems (Fraunhofer IOF’s industrial partner) to develop a novel system for tumor radiotherapy, which improves cancer patients’ chances of recovery. The scientists behind the project were awarded the Joseph von Fraunhofer Prize for the overall system, which is ready for production.

When using radiotherapy to treat tumors, physicians harness the destructive power of the radiation to kill the cancer cells in a targeted manner, thereby contributing to the curing of cancer patients. The aim is to destroy the whole tumor region while minimizing damage to healthy tissue − a delicate balance that requires the utmost precision. The success of the treatment largely depends on this level of precision and so medical staff generate an accurate image of the tumor beforehand using radiation-based computed tomography and then plan the treatment using these scans. When the radiotherapy takes place a few days later, the patient must be in the exact same position as they were for the initial examination. This position must not change during the therapy. The novel system developed by Fraunhofer researchers can continuously monitor the position of the patient both before and during radiation therapy. The chances of successful treatment and subsequent recovery are therefore significantly higher. In other words: it is a vital contribution to more effective cancer treatment that is gentler on the body. Dr. Peter Kühmstedt, Dr. Christoph Munkelt and Matthias Heinze from Fraunhofer IOF were awarded the 2022 Joseph von Fraunhofer Prize for the overall system, which was developed in collaboration with Varian Medical Systems and is production-ready. What particularly stood out to the jury was the relief provided to cancer patients who undergo this treatment.

A new precision method − fluorescence measurement technology for quality assurance in production

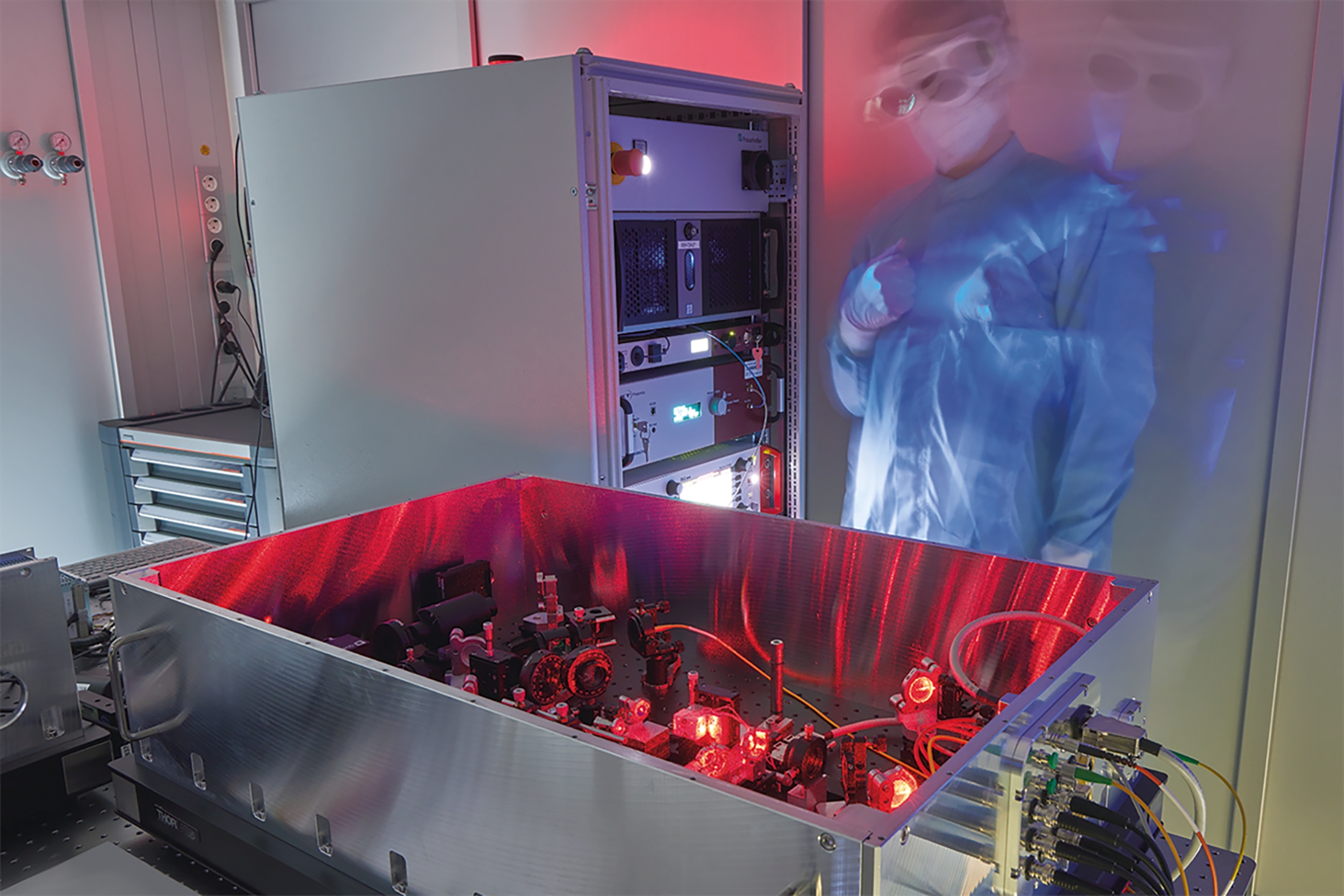

“Qualitative” and “quantitative” may be just a couple of letters apart, but the difference is huge. When it comes to fluorescence measurement technology, for example, it has so far been used almost exclusively for qualitative analyses. Now, for the first time, a team of researchers at the Fraunhofer Institute for Physical Measurement Techniques IPM is successfully using the method to obtain quantitative measurements with a high local resolution, and is receiving the Joseph von Fraunhofer Prize in recognition of this achievement.

Until now, fluorescence-based techniques have been seen as ways of obtaining estimates rather than as reliable quantitative measurement processes. Ultimately, calibrating the process requires not only precise references but also a profound understanding of the factors that influence fluorescent radiation. “We have succeeded in taking an imprecise process and developing it into a robust and extremely fast precision measurement method,” explains Dr. Albrecht Brandenburg of the Fraunhofer Institute for Physical Measurement Techniques IPM. It seems the world has been holding its breath for this. The technology is spreading both nationally and internationally at an astonishing pace, and sales in this area at Fraunhofer IPM are already in the millions. Dr. Albrecht Brandenburg and Dr. Alexander Blättermann have received the Joseph von Fraunhofer Prize for their achievement.

Always ready to receive – RFicient chips for a sustainable Internet of Things

Keeping things constantly connected to the internet costs energy − a lot of energy. Even small Internet-of-Things nodes run out of battery entirely in just a few weeks. All of this is changing with the RFicient® chip, developed by the Fraunhofer Institute for Integrated Circuits IIS, which saves power consumption by up to 99 percent. This development is a big step forward for the Internet of Things and has secured the Joseph von Fraunhofer Prize for the developer team.

Heaters and coffee machines that can be turned on or off using an app while on the move or on the couch? Waste containers with built-in fill level sensors that can autonomously detect when they need to be emptied and report this to waste collectors? Those are just two striking examples from the Internet of Things, or IoT: objects that are connected to the internet and send data to each other. The number of these wirelessly networked devices is growing rapidly, both among private consumers and in industry. For devices to be available at all times, however, their wireless receiver needs to be permanently switched on, which limits the battery life of small, battery-powered IoT nodes to just a few weeks.

The RFicient® chip, developed by the Fraunhofer Institute for Integrated Circuits IIS, represents a huge leap forward. “Our chip enables us to save up to 99 percent of power − so a battery that would have managed just over a month with conventional technology can now last ten years,” says Dr. Frank Oehler enthusiastically. The appeal of this product lies in the fact that, even with the extended battery life, the sensor node is still ready to receive signals at any time: it needs just 30 milliseconds to respond by performing an action. While other wake-up receivers are often switched off for minutes at a time and can sometimes take too long to respond, the RFicient® chip guarantees an immediate response. This is important not only in time-critical applications, but also in situations where there are many services running simultaneously or many different nodes being queried − such as at airports, train stations or football stadiums. This market-ready product, along with the registration of 16 patent families, has secured the Joseph von Fraunhofer Prize for the entire team, represented by Dr. Frank Oehler, Dr. Heinrich Milosiu and Dr. Markus Eppel.

Stifterverband Science Prize 2022

Virtually frictionless − virtual material probe sheds light on the friction gap

Ensuring that power plants operate without breaking down and that vehicles run energy-efficiently ultimately depends on just a few atoms. A virtual material probe makes it possible to see, and therefore control, tribological processes at the atomic level. A team of researchers from the Fraunhofer Institute for Mechanics of Materials IWM is being awarded the Stifterverband Science Prize 2022 for this development.

Friction and wear are all-pervasive in mechanical components. Because of this, mechanical seals for pumps or compressors make use of diamond coatings: The crystalline material protects components that rub against each other, allowing them to slide smoothly over one another, and therefore ensures a long service life. However, sharp fluctuations in the coefficient of friction, and in rare cases even total system failures, can cause damage costing millions of euros. The causes of these high coefficients of friction and the conditions needed to keep friction at a constant low level were not previously known. Now, a team of researchers has solved the diamond friction mystery using a virtual material probe. This combines simulations at multiple scales with real experiments and can effectively see into the gap between components as they come into contact − the only one of its kind. Prof. Michael Moseler and Prof. Matthias Scherge of Fraunhofer IWM are receiving the Stifterverband Science Prize 2022 for developing this probe. The third member of the team, Dr. Joachim Otschik of EagleBurgmann Germany GmbH & Co., will also be receiving the award.

Fraunhofer Founder Award 2021

Disinfecting seeds safely and sustainably using electron treatment

Chemical seed treatment rids seeds of fungi, viruses and bacteria. However, this comes at a high cost: The active agents used can also have harmful effects for farmers, the soil and the environment. On the other hand, electrons can be used to treat seeds in an environmentally friendly, sustainable and economical way − a method which helped the E-VITA GmbH start-up, a joint venture of the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP and Ceravis AG, to win the Fraunhofer Founder Award for 2021.

Should we just sow seeds without treating them first? It would not be a very good idea. This is because fungi, viruses and bacteria are present on the seed husks, which would result in a drastic reduction in yield. Seed producers tackle these pathogens using chemical seed treatments. However, this has its own disadvantages: Since the treatment sticks to the seeds, the farmer ends up handling potentially dangerous material when sowing them − this could harm the farmer, the natural environment and the soil. Restrictions should curb the environmental dangers: In groundwater protection areas, treated seeds are off-limits. Moreover, they must not be sown in strong winds as the treatment agent and additives might drift away, meaning that seed waste is classified as hazardous waste. In addition, a number of fungicidal seed treatments have already been banned − where there were previously over 20 groups of fungicidal active ingredients, there are now few left. However, they are not entirely out of use − as a consequence, emergency and special approvals are used to authorize the remaining seed treatments for use each year.

Chemical free, sustainable and field-tested

E-VITA GmbH, which is a joint venture of Fraunhofer FEP and Ceravis AG, should soon put an end to this procedure: Instead of using treatments to remove fungi and the like from seeds, they are looking to accelerated electrons as a chemical-free, sustainable, field-tested and economical alternative. Fraunhofer Venture and High-Tech Gründerfonds also noticed the direct social benefits and awarded the Fraunhofer Founder Award to the start-up.