Fraunhofer celebrates its 75th anniversary

The story of mp3

Looking back, it can be said that mp3 was the starting point for a whole series of audio codecs developed at the Fraunhofer Institute for Integrated Circuits IIS. Audio codecs store audio signals in a much more efficient way – that is, using less data – than, say, a CD. The global success of the original mp3 format was soon replicated by the second and third generations.

Today, these technologies are to be found in all consumer electronic devices. Meanwhile, the fourth generation of audio codecs is being launched and looks set to be another market hit. This ongoing success story is rooted in the scientific excellence of Fraunhofer IIS, which over the past 30 years has consistently won the race to set technical audio standards against competition that includes major international players. Key, too, has been the successful marketing of Fraunhofer research, with well over ten billion licensed devices in circulation worldwide.

The development of the white LED

When Prof. Jürgen Schneider from the Fraunhofer Institute for Applied Solid State Physics IAF presented one of his first white LEDs to a customer, the person in question mistook it for a “peculiar paper clip” and threw it away. Yet this invention would pave the way for cost-effective, energy-efficient and long-lasting white LEDs that are now indispensable in vehicle lights, streetlights and interior lighting.

It was in 1995 that the late Prof. Schneider and his team at Fraunhofer IAF succeeded in producing white light from just one light-emitting diode. Until that breakthrough moment, this could only be done by mixing three monochrome LEDs by means of a complicated regulator.

Fraunhofer IAF continues its research into efficient and reliable LED lighting. Right now, scientists are developing adaptive LED modules that adjust to human biorhythms.

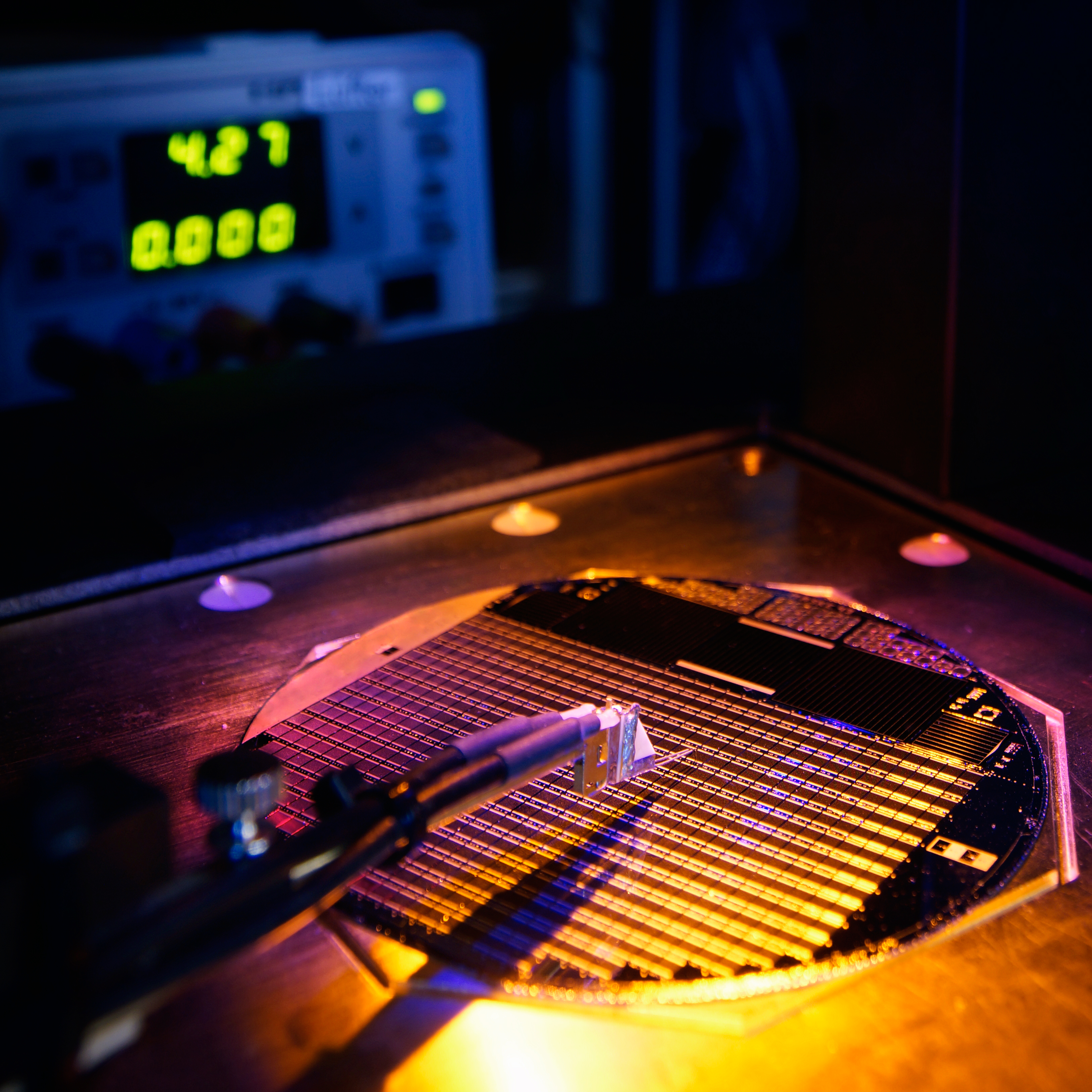

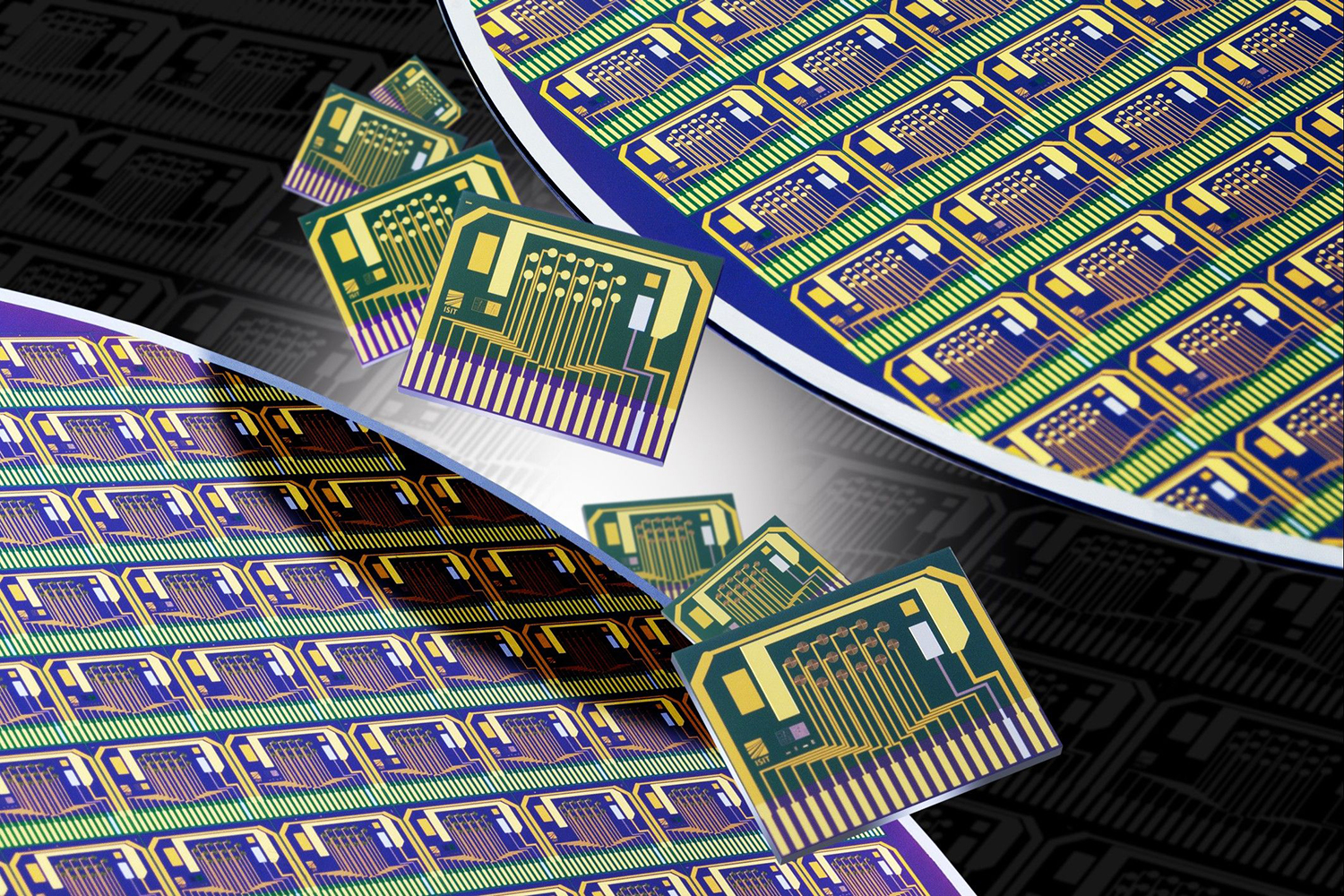

EUV lithography – New light for the digital age

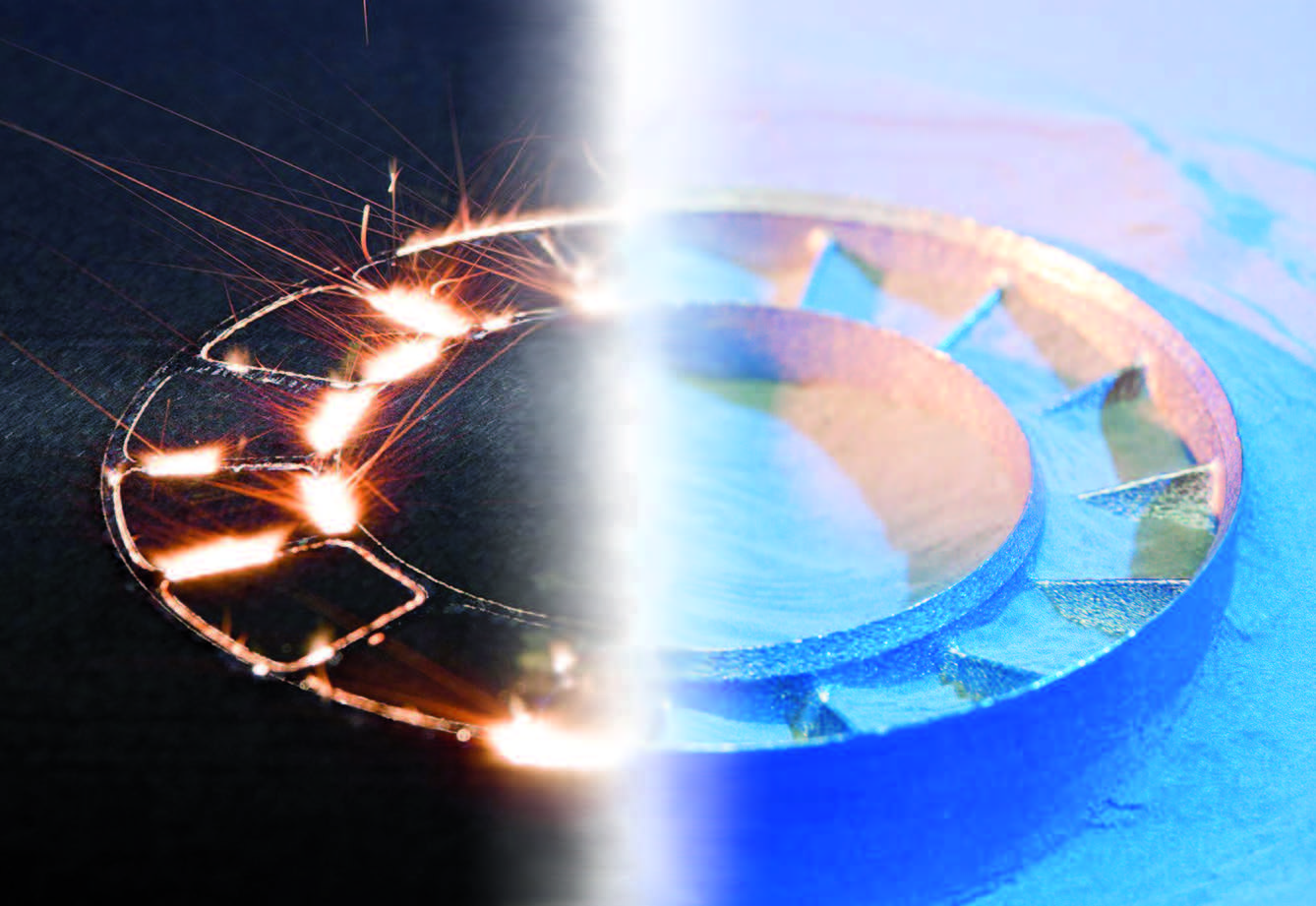

EUV lithography makes it possible to shrink microchips while improving performance and lowering both energy use and production costs — all of which are required for advances in artificial intelligence, autonomous driving, and 5G. The first smartphones with microchips manufactured using EUV lithography were launched on the market in 2019. This technology was developed at the Fraunhofer Institute for Applied Optics and Precision Engineering IOF in Jena in cooperation with Zeiss and Trumpf, two private-sector companies.

Fraunhofer researcher Dr. Sergiy Yulin had been working on complex layer systems for EUV optics with the aim of harnessing extremely short-wavelength EUV light for microchip production for 30 years. The breakthrough came with the use of the world’s strongest pulsed industrial laser, from Trumpf AG, and a highly precise collector mirror and projection optics from Zeiss. The new method makes it possible to transfer tiny three-dimensional structures just seven nanometers in size onto wafers. For comparison, a single strand of human hair averages 70,000 nanometers in diameter. The German president presented the German Future Prize in recognition of this innovative technology in 2020, marking Fraunhofer’s ninth such award.

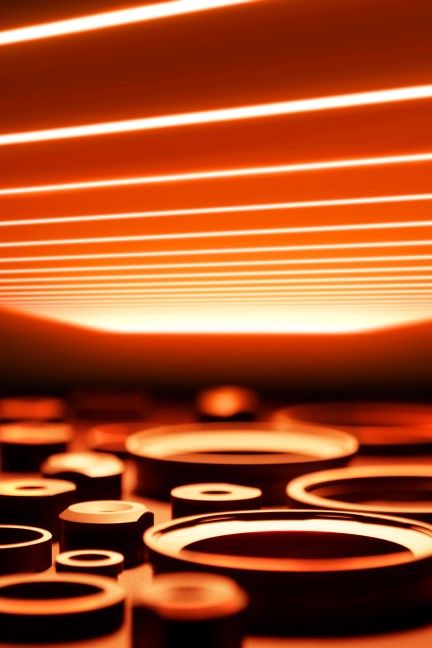

Beam-shaped light from advanced LEDs

High-performance LEDs have a long service life and are exceptionally efficient. In many areas, they are replacing conventional light sources such as halogen lamps and discharge tubes. Researchers at the Fraunhofer Institute for Applied Optics and Precision Engineering IOF in Jena have played a key role in this trend. Innovative primary and secondary optical systems developed at Fraunhofer IOF collect light from LED chips and then form it into a shape suitable for the specific application. For example, this system provides homogeneous illumination of both round and rectangular spaces while ensuring maximum brightness. In addition, the beam-shaping technology can be used for imaging applications.

Soon after development, the technology found commercial application in LED modules by OSRAM Opto Semiconductors. For its work, the joint research team was awarded the German Future Prize (Deutscher Zukunftspreis) for 2007.

HEVC – High Efficiency Video Coding

The use of compressed video data is increasing more rapidly than ever before. It already accounts for the lion’s share of bits on the Internet and in mobile data traffic. At the same time, the latest ultrahigh-definition TVs also use 4K Full HD. This trend toward higher-quality, higher-definition images and video content brings a steadily rising tide of data in its wake. In turn, this necessitates increasingly efficient techniques of data compression. The H.265/High Efficiency Video Coding (HEVC) standard is one such technique. Developed by the Fraunhofer Institute for Telecommunications, Heinrich Hertz Institute, HHI in partnership with big-name manufacturers in mobile communications and consumer electronics, it won a Primetime Engineering Emmy Award in 2017.

Work is currently under way to finalize the successor to HEVC, which goes by the name of Versatile Video Coding (VVC). Once again, Fraunhofer HHI is playing a major part. Scheduled for approval in 2020, VVC is projected to achieve a bit reduction of 50 percent compared to HEVC.

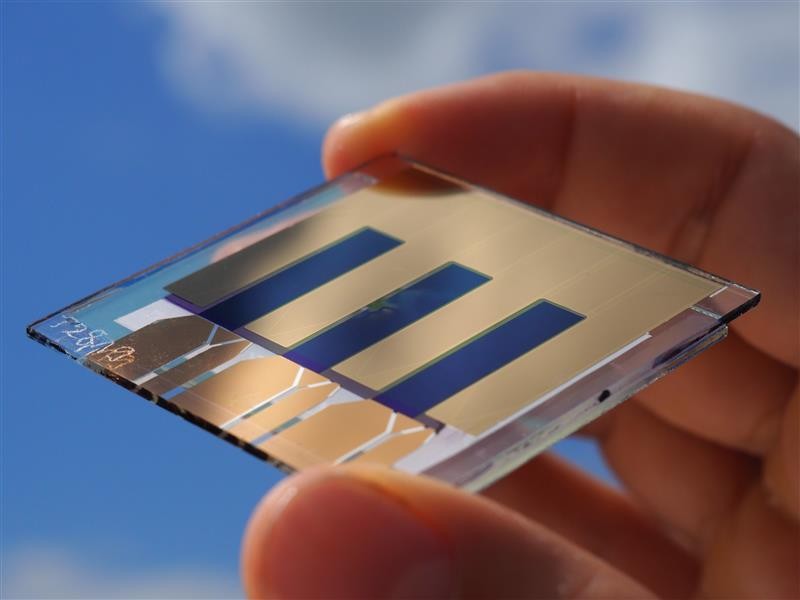

World record efficiency of 15.8 % achieved for 1 cm² organic solar cell

Organic photovoltaics (OPV) opens up new areas of application for solar energy thanks to its climate friendly and inexpensive production and its flexible and potentially transparent solar cells. To help this technology achieve a market breakthrough, research institutes worldwide are working to improve the efficiency and scalability of organic solar cells. Researchers at the Fraunhofer Institute for Solar Energy Systems ISE and the Materials Research Center FMF at the University of Freiburg have now improved their own efficiency record, announced back in September 2020, for an organic solar cell with an area of one square centimeter. Now, with a new record efficiency of 15.8 percent, the research team at Fraunhofer ISE has again set the world record in this category.

Research news July 18, 2023 Fraunhofer Institute for Solar Energy Systems ISE

A bionic handling assistant inspired by an elephant’s trunk

The best ideas are often supplied by nature. Inspired by the trunk of an elephant, the Fraunhofer Institute for Manufacturing Engineering and Automation IPA developed a bionic handling assistant, consisting of an arm, a joint and a gripper with three fingers. This gripping device can respond to contact with humans, first reducing pressure and then reapplying it straight away. It can therefore help with a whole range of tasks. There are potential applications for this highly flexible assistant in areas such as medicine, rehabilitation and care, as well as agriculture and in the home.

The concept is based on a patented IPA bellow actuator system that can only be manufactured additively. In developing and building the system, Fraunhofer IPA worked together closely with the industrial control and automation company Festo. The handling assistant was awarded the German Future Prize (Deutscher Zukunftspreis) in 2010.

E³ – rethinking industrial manufacturing

How do we sustainably maximize value creation while minimizing resource consumption?

For 13 Fraunhofer Institutes, the answer to this question was an integrated approach to manufacturing known as E3. The three Es stand for efficient processes and products, efficient factories and efficient working environments. In a project coordinated by the Fraunhofer Institute for Machine Tools and Forming Technology IWU, scientists worked from 2013 to 2016 on a variety of projects. These included integrated solutions for a comprehensive use of renewable energy in manufacturing, smart assistance systems to provide production workers with cognitive and physical support, and manufacturing techniques for an efficient use of materials and energy.

Many findings from the E³ lighthouse project have since become a benchmark and found their way into follow-up projects. These include SynErgie, which forms part of the Kopernikus program. Funded by the Federal Ministry of Education and Research, Kopernikus is Germany’s largest yet research initiative into new and sustainable forms of energy. Its aim is to provide science, industry and also private users with support for the rapid transfer of basic research into practical applications.

Data sovereignty with Industrial Data Space

Launched in 2014, the Industrial Data Space (IDS) initiative provides open data marketplaces for business, where data can be securely exchanged between trustworthy partners. The data sovereignty of all partners is guaranteed throughout the data chain. IDS partners from business and research have created an open standard for data sovereignty and a reference architecture for a secure data infrastructure. Elements of the IDS architecture, such as identity management, integrity and configuration of endpoints, logging and clearing of data transactions, and standardization, certification and auditability, are already used in cloud platforms and software services, thereby forming the cornerstone for fair and sustainable digital ecosystems. In addition, IDS plays a key role in helping to unlock the opportunities of artificial intelligence for the benefit of people and companies and also to counter its associated risks.

Vaccine production: Inactivating pathogens using low-energy electrons

Faster, ecofriendlier vaccine production with greater efficiency and lower costs is possible with a new technology developed by the Fraunhofer Institute for Cell Therapy and Immunology IZI, the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP, and the Fraunhofer Institute for Manufacturing Engineering and Automation IPA. The new technology makes it possible to inactivate pathogens within milliseconds using electron beams.

Toxic chemicals such as formaldehyde are often used to inactivate viruses in killed vaccines.

However, there are considerable disadvantages. The toxic substances destroy part of the external structure of the virus, but they harm the environment, even when disposed of correctly. They also require the vaccine to be extensively purified before use. On top of that, the inactivation process can take weeks or even months, depending on the virus.

The research team was honored with the Fraunhofer Prize for Human- and Environment-Centered Technology for their innovative method in 2021. This prize, which comes with 50,000 euros in prize money, is given out every two years by the Fraunhofer-Gesellschaft, the Fraunhofer Future Foundation, former board members, institute directors, and other supporters. It is awarded for achievements in research and development that improve people’s quality of life or help make our world more sustainable.

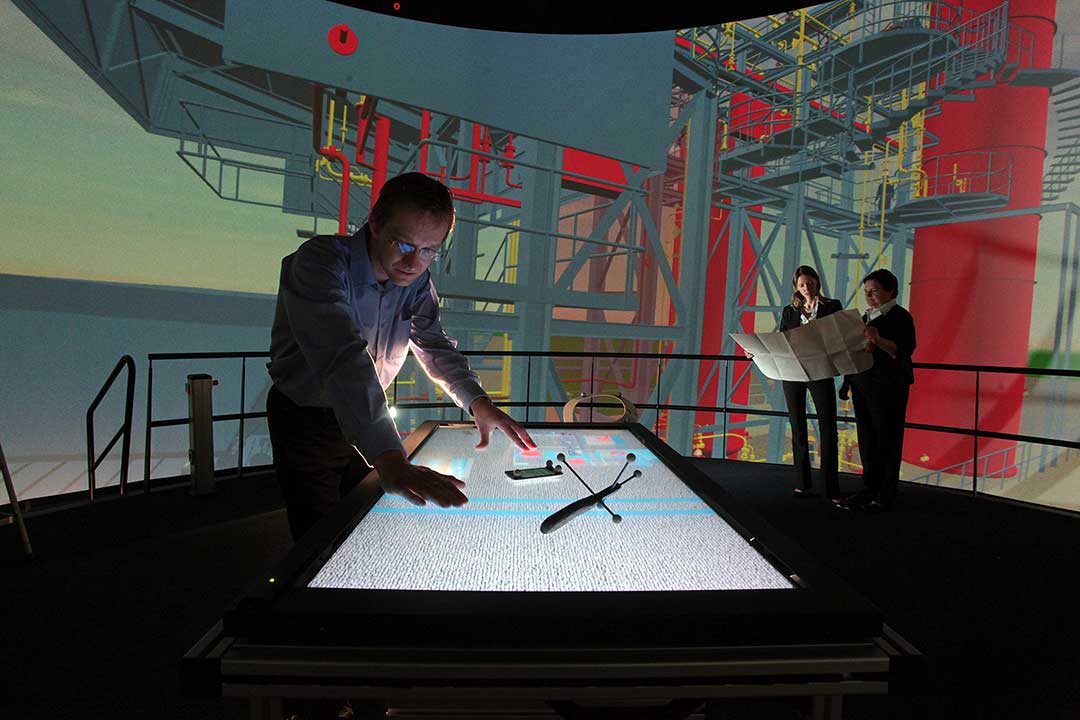

"Elbedome": virtual reality in 360 degrees

Virtual reality applications are playing an increasingly important role in manufacturing. With the opening of the Elbedome in 2006, the Fraunhofer Institute for Factory Operation and Automation IFF established Europe’s largest 360-degree projection system for industrial VR applications. At 16 meters in diameter and four meters in height, it featured a total projection surface of 250 square meters, which enabled the virtual representation of machines, factories or even whole cities.

Using this facility, developers, architects and engineers were able to immerse themselves in a virtual world and interact with digital prototypes of their products. This substantially reduced planning and development times.

In 2018, the system was extensively modernized and expanded to create a 3D mixed-reality laboratory. Now featuring stereoscopic video technology and a combined panorama and floor projection surface of over 450 square meters in area, this facility is able to create VR scenarios in genuine 3D. As a result, users now have the feeling of being completely immersed in the virtual environment.

Augmented reality in manufacturing

At the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart, researchers Florian Strieg and Günther Riexinger are busy developing AR solutions designed to help avoid errors and improve efficiency in production and assembly.

Developments include interactive applications for the creation and visualization of assembly instructions. For example, an augmented reality headset provides assembly workers with detailed instructions on how to assemble new components, thereby minimizing the amount of training required and also eliminating the need for printed instructions. This kind of interactive support for work processes is just one of several research projects at Fraunhofer IPA that are aiming to simplify and accelerate assembly, maintenance and planning tasks..

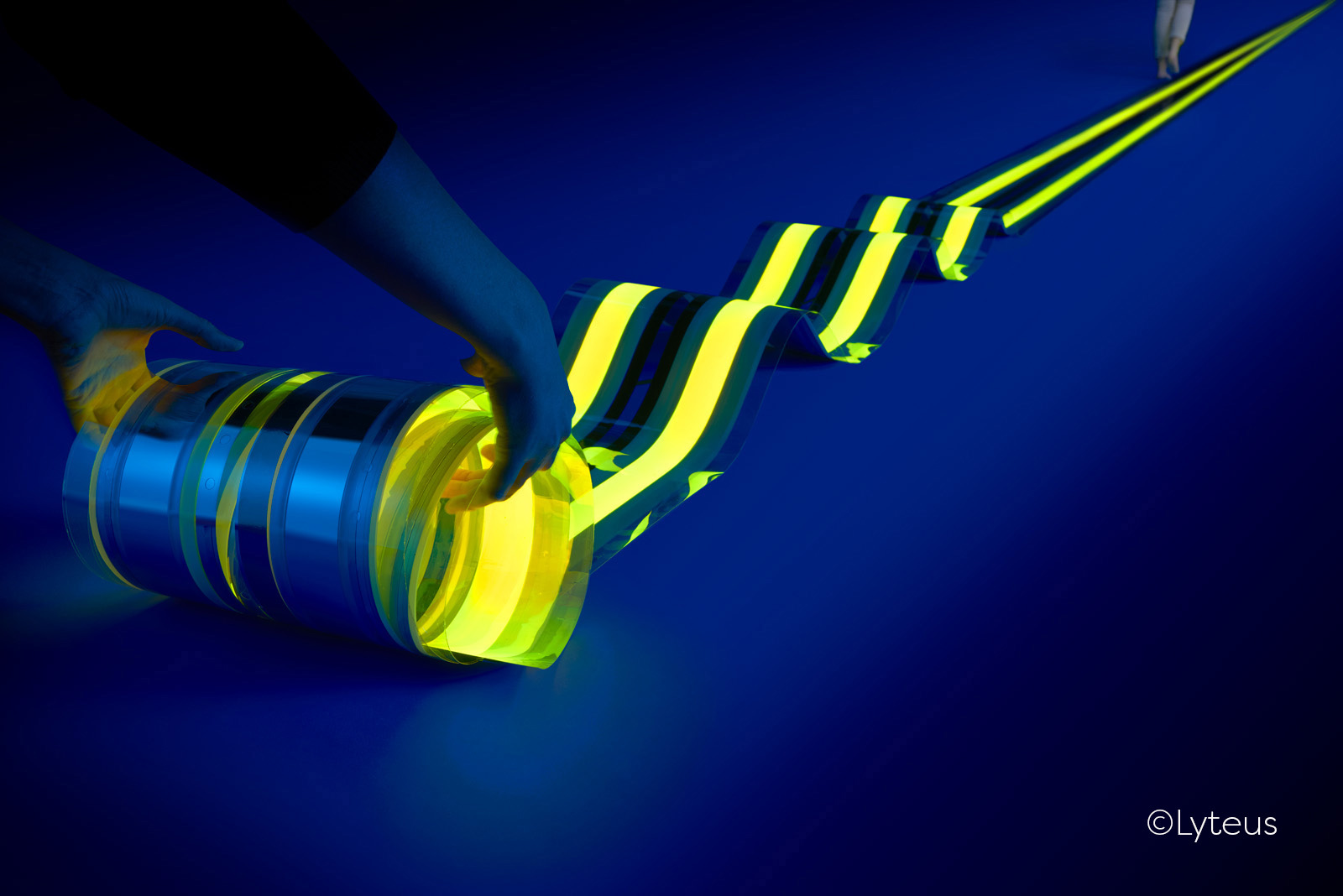

Foiling hardware hackers

The Internet is not the only source of danger for IT systems. Sensitive data can also be jeopardized by a manipulation of hardware. Hackers will even go so far as to drill into hardware and tap data directly from the conductive tracks of printed circuit boards (PCBs).

Working in collaboration with the High-Performance Center for Secure Connected Systems, the Fraunhofer Institutes AISEC, EMFT and IMS have now developed a special foil that protects PCBs against such attacks. Before each restart, the foil automatically checks whether it is intact. To do this, it uses a unique material fingerprint that is created during manufacture as a physical unclonable function (PUF). Only when the PUF is intact can the data be decrypted. If the foil is damaged, the key is lost.

Security experts at Fraunhofer are now working on ways of combining a wide variety of PUF technologies so as to obtain an even higher level of protection.

Hyperspectral optics for advanced satellite observation

Industrialization has increased the impact of humans on the environment and vegetation, with major consequences for agriculture and food production. Revealing these complex relations and analyzing them presents science with new challenges. Satellite-based hyperspectral optics developed by the Fraunhofer Institute for Applied Optics and Precision Engineering IOF can make an important contribution here. Unlike conventional spectrometers, the DLR Earth Sensing Imaging Spectrometer (DESIS) possesses a total of 235 spectral channels, each with a bandwidth of 2.5 nanometers. It can therefore cover the entire spectrum from visible to near infrared.

DESIS is able to map land surfaces, oceans and the Earth’s atmosphere with great precision. Using this data, scientists can investigate the dynamic relations between geophysical parameters on an intercontinental scale.

As of June 2018, DESIS has been observing the Earth’s surface from aboard the International Space Station (ISS)..

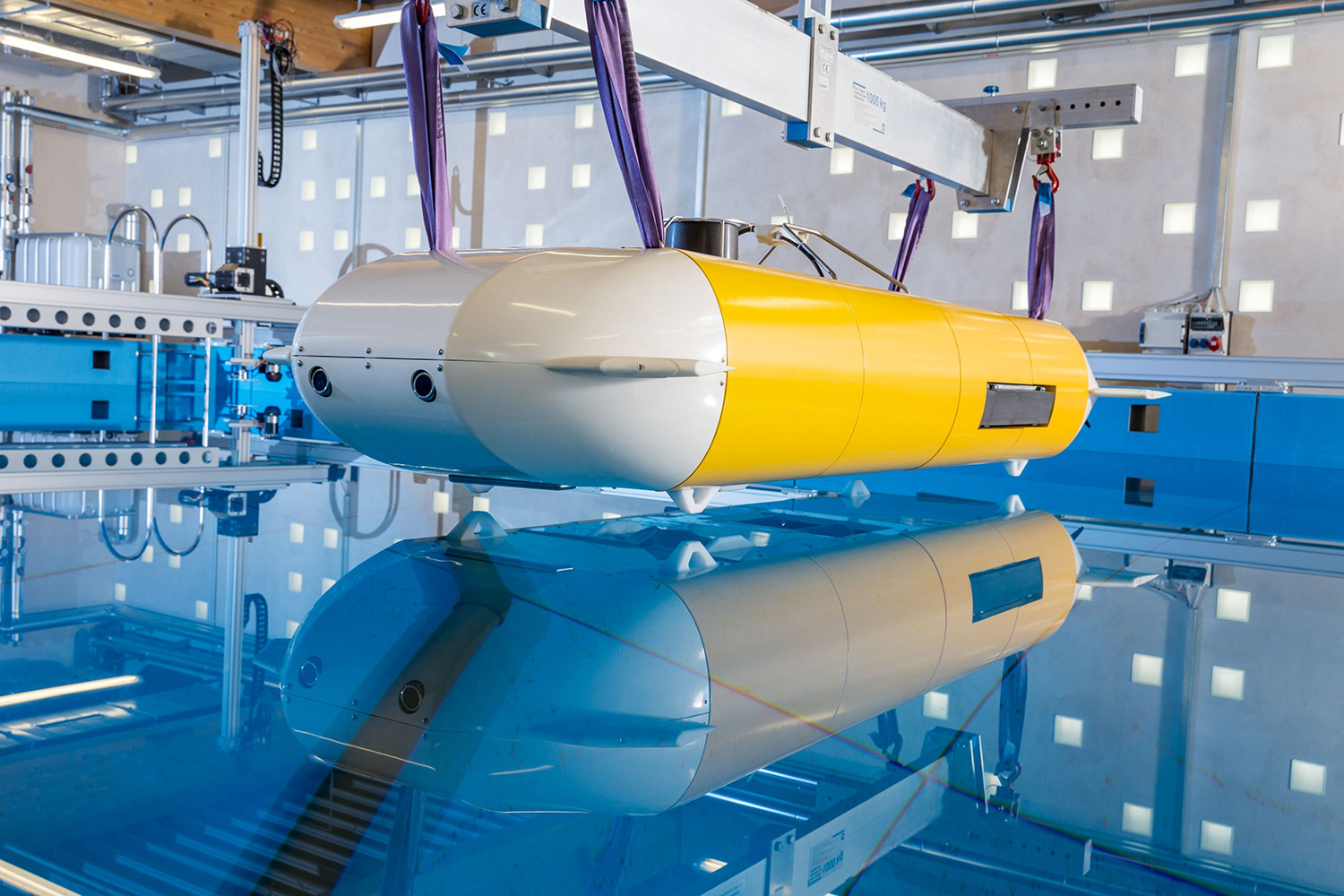

Deep-sea diver: DEDAVE explores the ocean floor

DEDAVE stands for “Deep Diving AUV for Exploration.” It is an autonomous underwater vehicle for exploring the ocean floor at great depths. It can dive to a depth of 6000 meters and is used to survey undersea cables and pipelines as well as raw materials and wrecks. Developed by the Fraunhofer Institute for Optronics, System Technologies and Image Exploitation IOSB-AST in Ilmenau, DEDAVE boasts a range of impressive features such as an open frame architecture, tool-free access to the payload section and rapid redeployability.

In 2017, a licensing agreement was concluded with the Canadian company Kraken Robotics, which will use DEDAVE as the basis for its own Thunderfish program. In addition, a framework agreement on research and development was also signed. The DEDAVE project has given Fraunhofer a foothold in the market for underwater robotics, which was previously dominated by foreign companies.

A commercial deployment of DEDAVE in October 2017 helped discover historic test models of the Avro Canada CF-105 interceptor aircraft in Lake Ontario. In 2018, DEDAVE was nominated for the Thuringian Innovation Award (Thüringer Innovationspreis).

A world record for converting sunlight into electrical energy

Scenarios for future energy supply are all based on solar power as one of the two main pillars, alongside wind. The cost of solar power has plummeted by 75 percent since 2006, driven down by technological advances, economies of scale, and the benefits of experience. Photovoltaic power plants in Germany are now able to provide energy at a competitive price of four to five euro cents per kilowatt hour. The Fraunhofer Institute for Solar Energy Systems ISE, Europe’s largest solar research institute, has been a major part of this story for many years now.

In the period since the institute was founded in 1981, it has repeatedly set new records for solar cell efficiency and contributed to the global success of photovoltaics. Back in 2017, it set the world efficiency record for multicrystalline silicon solar cells, currently at 22.3 percent. And it also holds the world record for converting sunlight into electrical energy, which stands at 46.1 percent. Fraunhofer ISE experts achieved this feat under concentrated sunlight with a multi-junction solar cell based on III-V semiconductors.

Taraxagum – tires made of dandelion rubber

The TaraxagumTM project is all about a plant commonly known as the Russian dandelion. What makes this plant so special is the milky liquid – or latex – inside it, which contains large quantities of rubber. The story begins with Dirk Prüfer, professor at the Westfälische Wilhelms-Universität Münster and department head at the Fraunhofer Institute for Molecular Biology and Applied Ecology IME. He and his team joined forces with plant breeder ESKUSA, tire manufacturer Continental Reifen Deutschland and the Julius Kühn Institute. Their aim was to test the use of the Russian dandelion as an alternative source of natural rubber. In so doing, they turned this wild plant into a useful crop within the space of just a few years.

Car, truck and bicycle tires made of this rubber have all come through the requisite tests. The success story continued with the official opening, in late 2018, of the Taraxagum Lab Anklam, a Continental research and testing facility. The use of locally extracted natural rubber will cut down on shipping miles and therefore reduce carbon emissions.

Sweet lupines: delicious and rich in protein

A team of researchers at Fraunhofer IVV developed a unique method that enables the use of high-quality proteins in foods. Thanks to this groundbreaking technique, they are free from bitter-tasting compounds. The food industry now manufactures a wide variety of products from sweet lupine proteins. These proteins are highly suitable for the production of purely plant-based alternatives to yogurt, cream cheese, milk, desserts and ice cream. In 2014, the Fraunhofer team received the German Future Prize (Deutscher Zukunftspreis) in recognition of this breakthrough.

Starting in 2006, the Fraunhofer Institute for Process Engineering and Packaging IVV has also set new standards in the manufacture of cooked-meat products with a fat content of less than three percent. The meat comes exclusively from ham, which is particularly rich in essential amino acids. Using a special technique, they have succeeded in producing tasty and succulent cooked-meat products despite the lack of fat.

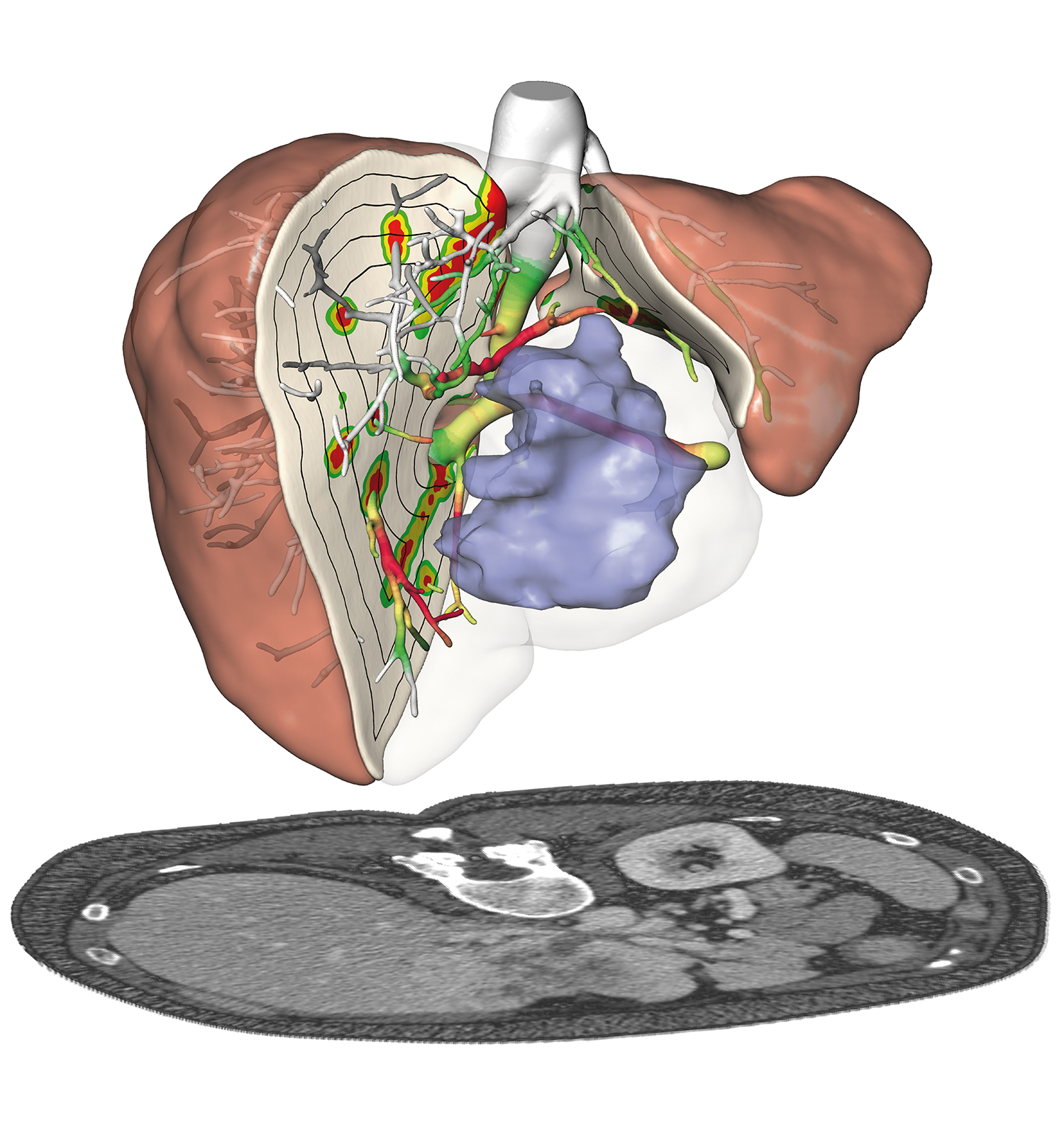

Algorithms for liver surgery mean safer procedures worldwide

Liver cancer is the world’s second-leading cause of cancer-related deaths. And, unlike other cancers, its incidence continues to rise. Given the liver’s complex vascular system and the fact that tumors are often hard to reach, resection can be a difficult task for surgeons.

The Fraunhofer Institute for Digital Medicine MEVIS has developed software that analyzes radiological data. This enables surgeons to plan ahead for difficult procedures and minimize the risk of postoperative liver failure. The software has been available in hospitals since 2014 in the form of a commercial product marketed by an industry partner. Clinicians around the world joined forces to develop a standard that is now known in liver surgery as the MEVIS analysis. In 2018, MEVIS researchers were presented with the Joseph von Fraunhofer Prize for their work in this field.

High-power fiber lasers

Fiber lasers provide a powerful source of radiation for applications in science and industry. Key applications for fiber lasers include laser material processing in manufacturing.

In other sectors such as aerospace and medicine, there is also a strong demand for high-power, efficient and robust lasers providing a high beam quality. To meet this need, researchers at the Fraunhofer Institute for Optics and Precision Engineering IOF in Jena have developed a new generation of laser systems with improved parameters. These fiber laser systems reach power outputs of several kilowatts with a beam quality that is virtually diffraction-limited.

In 2013, a project team from Fraunhofer IOF and Friedrich Schiller University Jena was honored with the German Future Prize (Deutscher Zukunftspreis) for its research into ultrashort pulse lasers for industrial-scale production. The team developed laser-based tools that emit light in ultrashort energy-charged bursts. Fraunhofer IOF has been conducting cutting-edge research into high-power fiber lasers for some 20 years now.

Spatial hearing with binaural hearing aids

Prof. Birger Kollmeier (Fraunhofer IDMT and University of Oldenburg), Prof. Volker Hohmann (University of Oldenburg) and Dr. Torsten Niederdränk (Siemens Munich) teamed up to develop a hearing aid system that delivers a natural auditory experience. For their work, they received German Future Prize (Deutscher Zukunftspreis) in 2012.

Their development marked a genuine revolution: a hearing aid system fitted to both ears. The two hearing modules communicate via wireless technology, thereby obviating the need for cumbersome wires. Spatial hearing is the result of the time difference between the arrival of a sound at the left and at the right ear. The digital processing technology in the hearing aid system renders this difference in real time, thereby creating a natural and properly spatial auditory experience. Furthermore, it enables users in busy and noisy environments to concentrate on a single speaker and blend out background noise.

Biosensor measures blood sugar without a needle

Researchers at the Fraunhofer Institute for Microelectronic Circuits and Systems IMS in Duisburg have developed a miniature biosensor that makes life considerably easier for diabetics. The 0.7 x 10 mm sensor is inserted beneath the eyelid, where it continuously measures glucose levels in the lacrimal fluid. This eliminates the need for an unpleasant jab in the finger to extract a drop of blood for a test strip. The sensor comprises the entire diagnostic system, including an analog-digital converter that digitalizes the electrochemical signal and transmits it wirelessly to a mobile reader device. Patients can therefore keep tabs on their glucose level at all times.

Following comprehensive testing, the clinical validation of the measurement principle was completed in mid-2018. As a next step, the researchers want to further shrink the sensor chip and mobile reader. The ultimate goal is approval as a medical device. Development work is being carried out in cooperation with the startup NovioSense, in which Fraunhofer holds a stake.

The world’s largest OLED panel

For the past 15 years, scientists at the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP have been researching the field of organic electronics. In 2011, they mounted the world’s largest OLED panel on a 330 x 330-millimeter glass surface and then integrated this in a lamp. Fraunhofer has know-how in various aspects of this technology. These include manufacturing, with pilot production lines for sheet-to-sheet, wafer and roll-to-roll processing. In addition, the integration of sophisticated electronics has given rise to new applications in such areas as medical engineering, interior design and car taillights.

Researchers at Fraunhofer FEP are also investigating the incorporation of organic semiconductors into silicon CMOS backplane wafers. This has already resulted in the development of low-energy microdisplays for use with wearables and microdisplays with extended Full HD resolution for data headsets or AR/VR applications.

Fraunhofer FEP is also currently working on the deposition of organic components on biodegradable foil substrates for active implants.

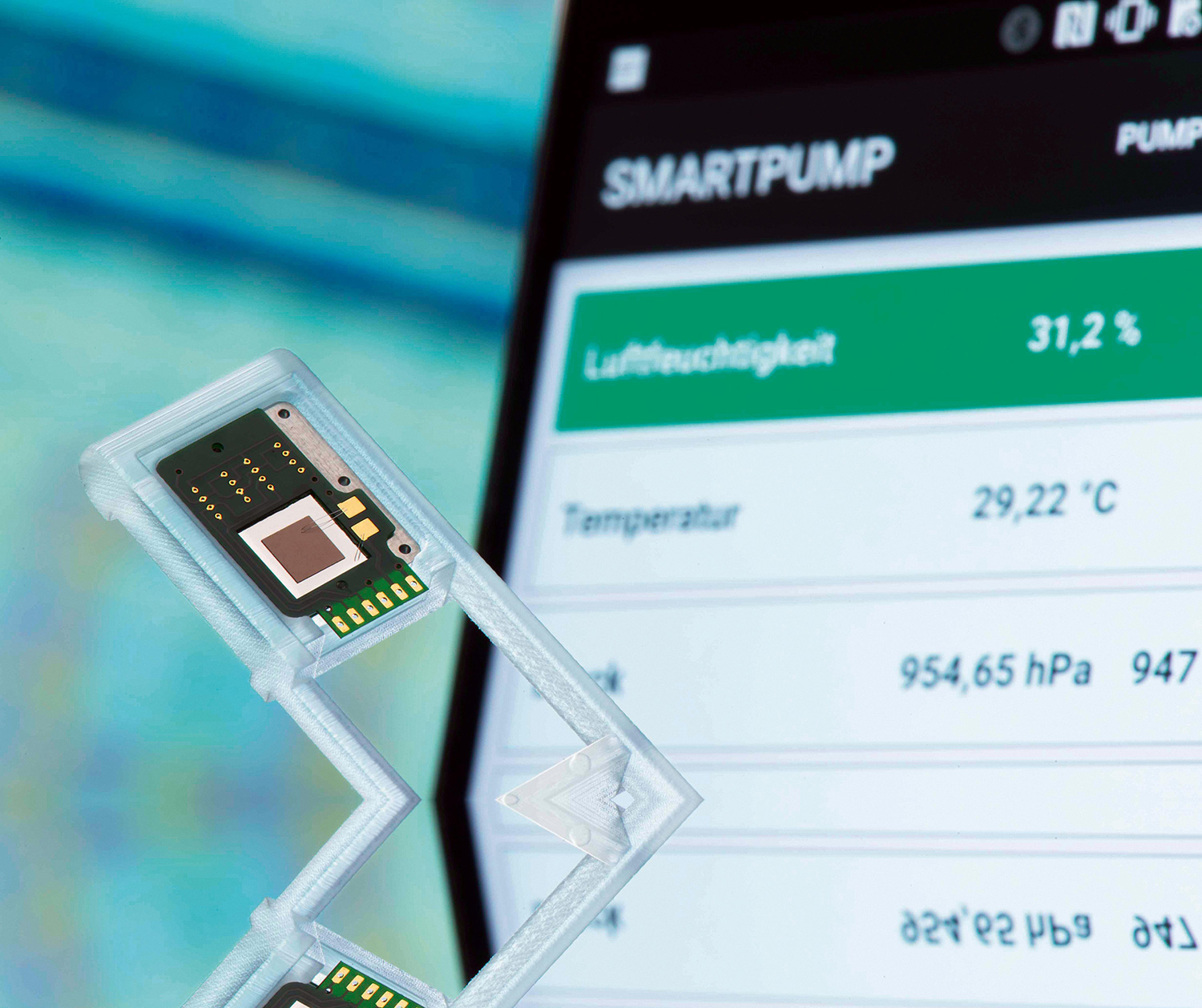

A high-pressure micropump for demanding applications

Researchers at the Fraunhofer Research Institution for Microsystems and Solid State Technologies EMFT have developed an extremely small and high-performance MEMS micropump that generates a pressure of up to six bars (fluids) or one bar (air). The micropump has a capacity of 50 nanoliters – roughly a thousandth of a drop of water – and therefore enables highly precise dosing in applications such as the administering of drugs in pain and tumor therapy or of hormones such as insulin. Further applications include an ancillary role in gas sensors for mobile devices and metering the dosage of lubricants in machine spindles.

Fraunhofer EMFT has been developing piezoelectric micropumps since the mid-1990s. In 2011, using what was then the world’s smallest silicon micropump (7 x 7 x 0.8 mm), the institute was able to generate such high pressures that the pump was almost bubble-independent – the first time such a feat had been achieved. Today, the smallest pump in the institute’s portfolio measures a mere 3.5 x 3.5 x 0.6 mm.

Strong bonds with DiaCer®

Composite materials combine the specific advantages of each of their individual components. For example, ceramics and diamonds, as separate materials, both offer outstanding qualities for industrial manufacturing. When combined in composites, these qualities are enhanced even further.

In a project coordinated by the Fraunhofer Institute for Surface Engineering and Thin Films IST and involving the participation of the Fraunhofer Institutes IKTS, IPK and IWM, the aim was to develop ceramic tools with a diamond coating. This led to the creation, together with partners from industry, of the composite material DiaCer®. This is based on ceramic substrates made of silicon nitride or silicon carbide, onto which a polycrystalline diamond coating is deposited using the hot-filament CVD technique developed by Fraunhofer IST.

A diamond-coated mechanical seal was developed in partnership with the companies EagleBurgmann Germany and CONDIAS. This groundbreaking innovation has been recognized with various prizes for technology transfer. It is marketed worldwide under the name DiamondFaces®.

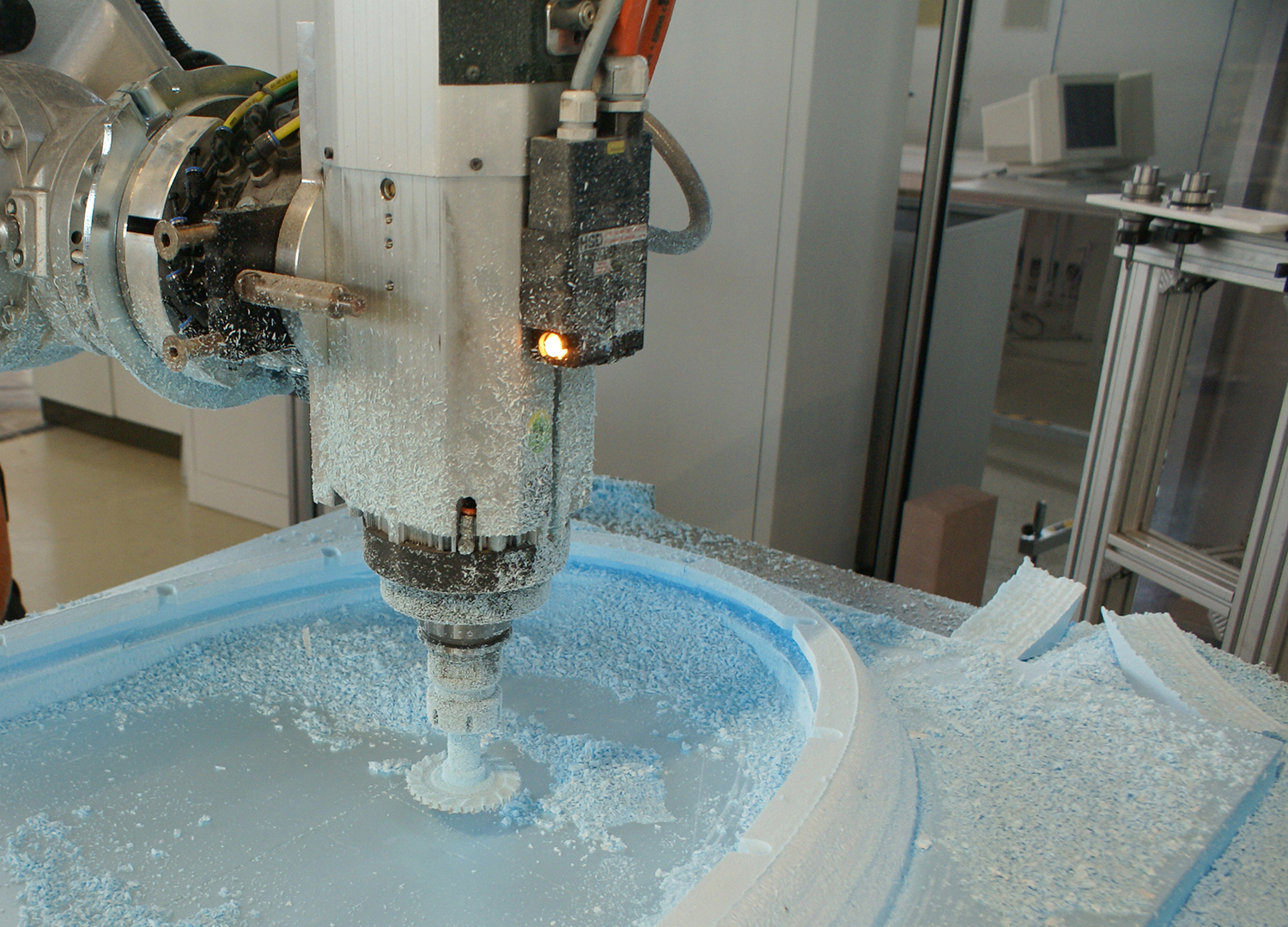

3D printing with robots

Originally developed for ancillary tasks in production and handling, industrial robots have come to take on increasingly challenging tasks. Today, they offer a highly flexible and relatively low-cost option for the manufacture of large components. Fraunhofer IFF was among the first to investigate the use of robots as machine tools and has since made them a viable production option, in particular for small and medium-sized manufacturers eager to investigate more-efficient ways of making models and casting molds.

With the development of robots for additive layer manufacturing (ALM), Fraunhofer IFF has now taken this technology into new areas of production. ALM overcomes the restrictions on manufacturing volume that limit conventional additive manufacturing. Moreover, the direct manufacture of large and complex components eliminates costly intermediate steps and, in particular, makes it possible to produce prototypes and small batches in a cost-effective manner. Commercial applications of this technology already exist in the area of tool and mold making, and in the furniture industry.

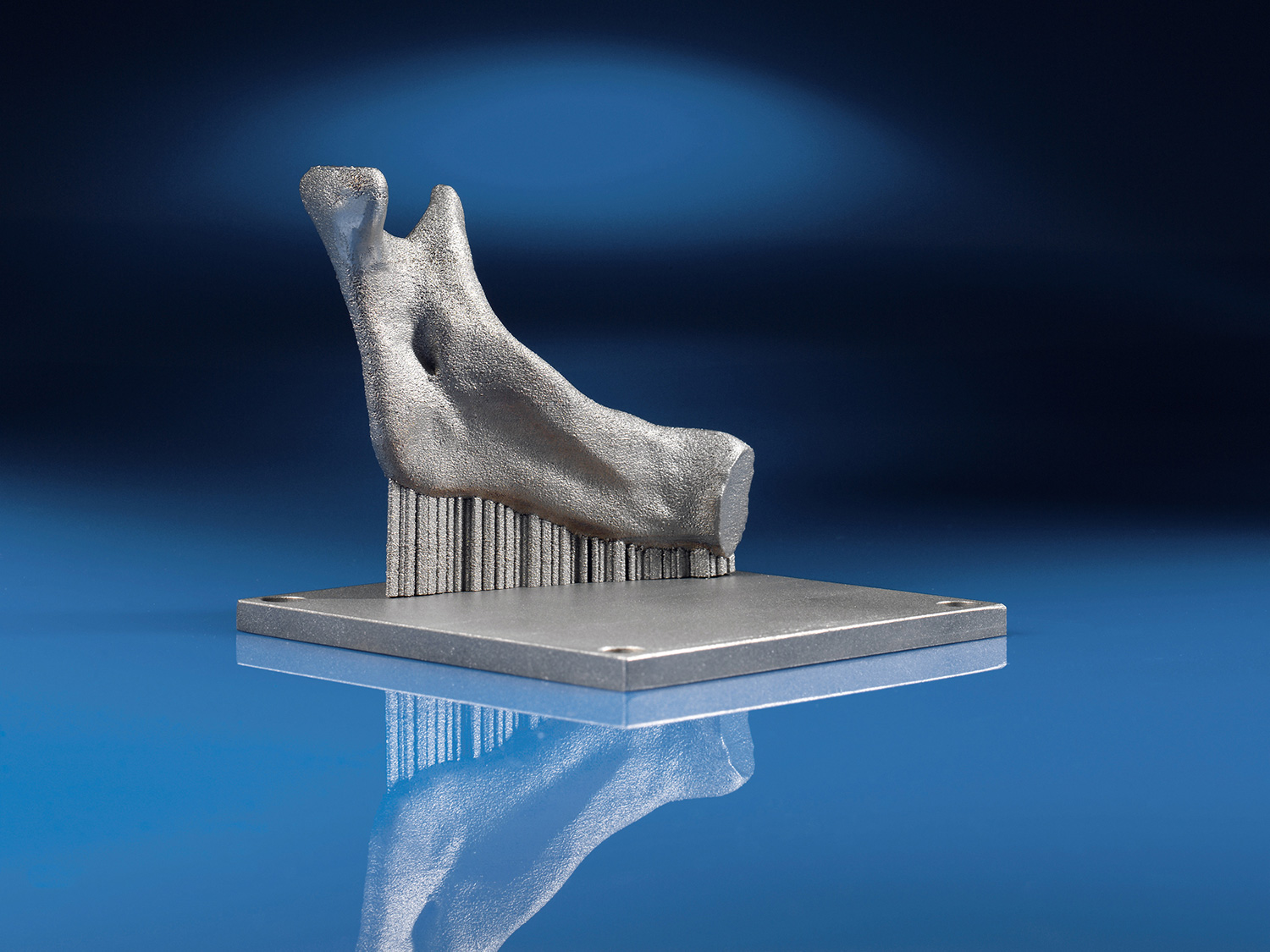

3D printing with metal

In the early days, additive manufacturing was based on plastics. Since the mid-1990s, however, metal-based 3D printing has also been part of the program at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM.

Back in 2007, Fraunhofer IFAM used the technique of laser beam melting (LBM) to produce a partial replica of a jawbone. Made of a titanium alloy, this prototype implant showcases the properties displayed by additive manufactures with complex inner structures. In this particular case, the filigree structure not only reduces weight while preserving component strength but also provides reservoirs either for the long-term administration of medication or to encourage the formation of new bone tissue.

In recent years, the range of materials has been substantially expanded and the process-control technology further enhanced, so that LBM is now a certified, state-of-the-art technique for implant manufacture.

Lab on a chip

A chip capable of analyzing biological processes without any additional components was awarded the German Future Prize (Deutscher Zukunftspreis) for 2004. This lab on a chip was developed at the Fraunhofer Institute for Silicon Technology ISIT. The ISIT researcher Dr. Rainer Hintsche together with Dr. Walter Gumbrecht from Siemens and Dr. Roland Thewes from Infineon were the named recipients of the award. Their pioneering development was preceded by years of research in a major program funded by the German Federal Ministry of Education and Research and involving the input of chemists, biochemists, physicists, electronic engineers and equipment manufacturers.

In the intervening period, there have been numerous projects to advance this technology, culminating in the creation of the Fraunhofer spin-off eBiochip. Further developments include portable devices for environmental analysis produced by the company Bruker Daltonik. In 2016, a further spin-off, CAMPTON Diagnostics, was founded. This is developing a point-of-care platform for diagnostic applications.

A cryobank for biomaterials

Over 20 years of interdisciplinary research and development in cryotechnology at the Fraunhofer Institute for Biomedical Engineering IBMT culminated in the establishment of the Fraunhofer BioArchiv, a leading international alliance of biobanks.

The Fraunhofer BioArchiv is currently the only system provider of cryogenic biobanks for therapeutic and diagnostic purposes that operate at temperature ranges below minus 130 °C. Fraunhofer IBMT also develops new cryomedia and enhanced freezing protocols for partners from industry and research, provides cryostorage facilities for biomaterials, and assists customers with planning, validating and setting up their own cryobanks.

BioKryo, a spin-off founded in 2010, also provides cryostorage of valuable biomaterials such as stem cells or tissue samples. Customers from the biotech and pharmaceutical industries use these cryostorage facilities for a variety of purposes, such as storing backups for their cell lines.

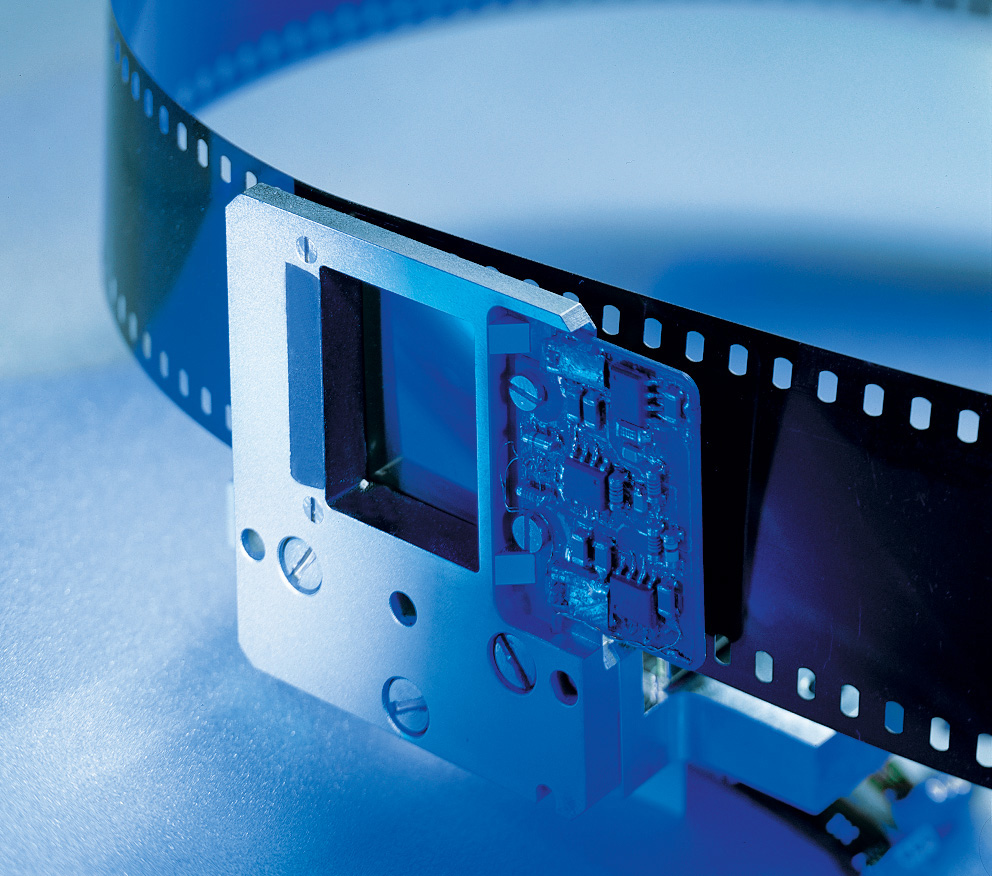

The laser film recorder – ushering in the age of digital movies

A mere 25 years ago, movies were almost exclusively analog. However, with the advent of digitally created special effects, filmmakers suddenly needed a system to write digital images onto film material. The solution was developed by the Freiburg-based Fraunhofer Institute for Physical Measurement Techniques IPM together with ARRI, the Munich specialist for filmmaking technology. The ARRILASER digital film recorder was used to transport the dinosaurs into the analog film world of Jurassic Park. Back then, moviegoers were amazed at the quality of the reproduction.

Fraunhofer IPM and ARRI were presented with the Oscar for scientific and engineering achievement in filmmaking. Today, with most films produced and screened digitally, the ARRILASER is seldom required. However, Fraunhofer IPM is still busy developing extremely fast and precise optical measurement systems – and, as ever, rolling back the boundaries of technology.

A breakthrough in airbag development

Airbags help prevent serious head and body injuries. Whenever an airbag ignites, this is down to research carried out at the Fraunhofer Institute for Chemical Technology ICT at the end of the 1980s. Researchers there developed the enhanced gas mixtures for the gas generators used to inflate airbags. Based on new organic compounds, these mixtures require double ignition. This delay in ignition makes it possible to control gas generation in such a way that the speed of airbag inflation can be varied. This helps reduce the severity of so-called out-of-position accidents – when, for example, in the seconds before a crash, the front passenger leans forward to remove something from the glove compartment. The research at Fraunhofer ICT also enabled the development of passenger airbags, side airbags and airbags offering specific protection for the head or knees. Fraunhofer ICT has staged the airbag2000+ conference since 1992, an event that in some years has attracted over 1000 visitors.

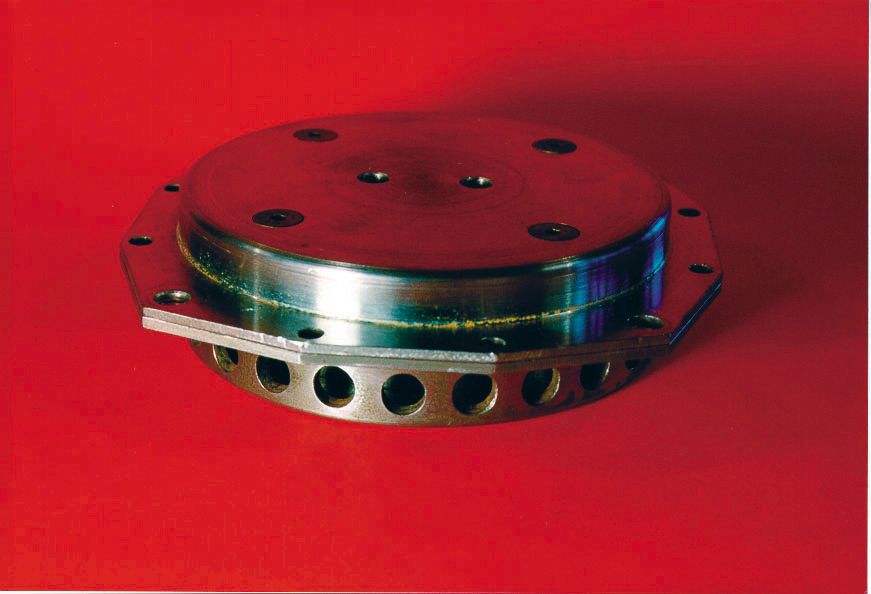

A CMB machine for producing steel parts

By the late 1990s, the curtain was starting to fall on conventional rapid tooling in manufacturing industry. In particular, this technique struggled to cope with last-minute design modifications and complex geometries. Manual deposition welding was slow and imprecise, and subsequent finishing by means of milling or spark eroding no longer met industrial specifications.

In early 2000, the Fraunhofer Institute for Production Technology IPT came up with a process known as controlled metal build-up (CMB). This technique combined laser deposition welding with high-speed milling in a single solution. Using this hybrid machine, it became possible to manufacture, laser for layer, steel components with complex geometries and machine them to a high precision.

CMB machines are now on offer from a number of machine tool manufacturers. At Fraunhofer IPT, meanwhile, the quest to enhance this technology continues. Developments include a wire-based laser metal deposition module for integration in commercially available robot systems or milling machines.

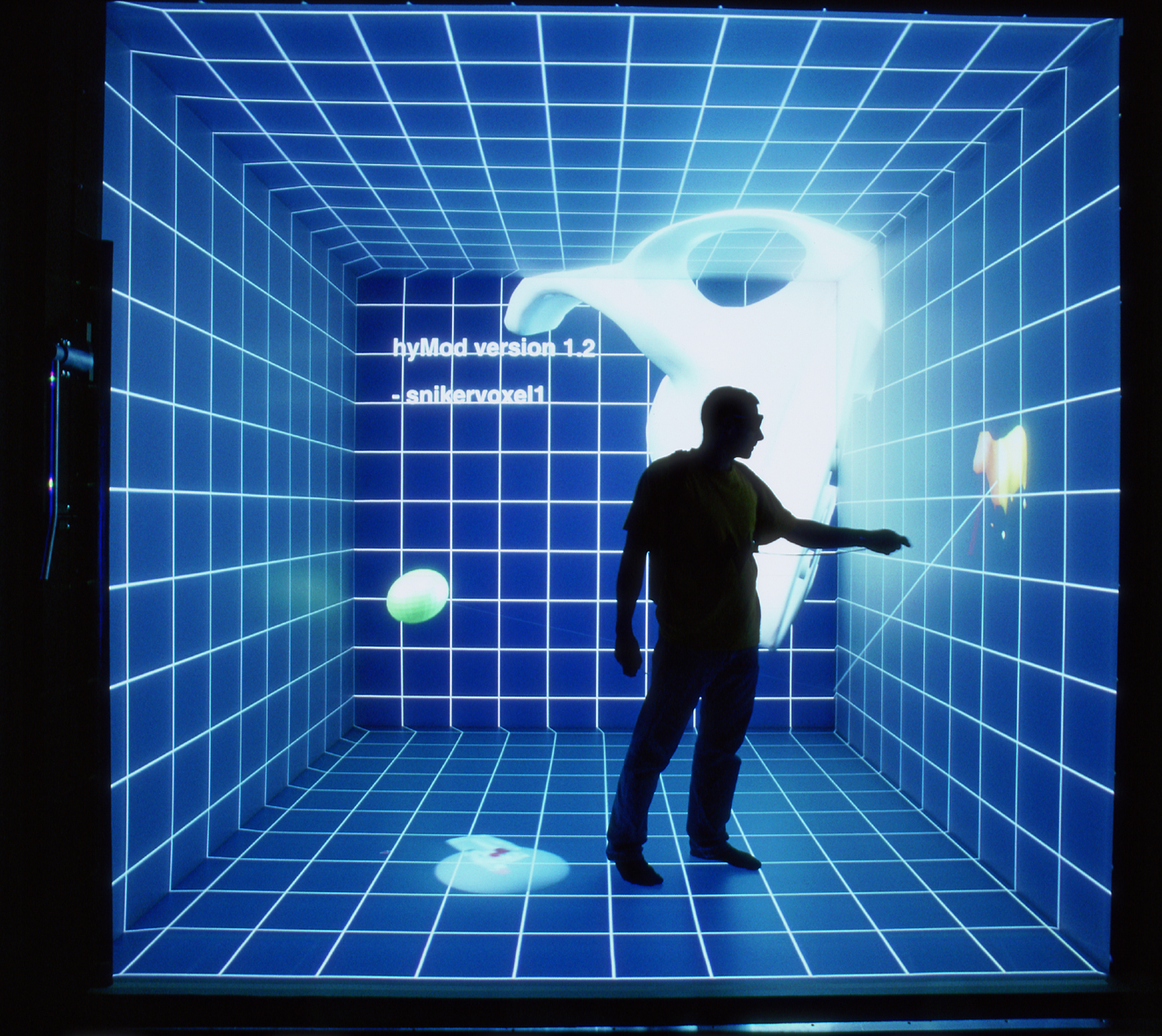

Personal Immersion: PC-based virtual reality

Until the late 1990s, virtual reality (VR) was beyond the reach of most companies, not least because the requisite computing power and graphics were still prohibitively expensive. In response, the Fraunhofer Institute for Industrial Engineering IAO began developing its own PC-based VR architecture. In the year 2000, the institute presented Personal Immersion, the world’s first workable PC-based VR system.

Thanks to its cluster architecture, the system was scalable. In addition, it could be used with multiscreen projection systems. In 2001, Fraunhofer IAO therefore unveiled its very own cave automatic virtual environment (CAVE). This was the first ever PC cluster-operated CAVE solution. Personal Immersion paved the way for the use of VR in small and medium-sized companies.

Previously, Fraunhofer IAO had also developed a virtual reality framework by the name of Lightning, which enabled the rapid generation of 3D environments. This won the Joseph von Fraunhofer Prize in 1999. Today, Fraunhofer IAO is working on advanced CAVE applications for the visualization of large-scale environments for major projects.

Additive manufacturing for personalized ceramic implants

Back in the 1990s, the Fraunhofer Institute for Ceramic Technologies and Systems IKTS began looking at additive manufacturing as an economically viable method of producing small batches of ceramic components with complex geometries. Initially, research concentrated on the adaptation of existing techniques for ceramics. Today, however, the emphasis lies on the use of advanced combinations of materials and techniques in order to produce, among other things, customized implants. This involves coating a porous structure with a solid shell. The bone-like exterior of the implant is produced by means of lithography-based ceramic manufacturing (LCM) and according to individual patient specifications.

The sponge-like interior is created by a technique known as freeze-foaming. Here, a suspension is first foamed and then freeze-dried. Implants produced in this way have a porous structure that encourages cell growth while remaining sufficiently rigid and stable. They offer a promising solution for bone cancer treatment and for oral and maxillofacial surgery.

Rapid manufacturing with laser technology

In today’s manufacturing industry, companies need a fast and efficient means of producing prototypes and small batches of complex or customized components. The Fraunhofer Institute for Laser Technology ILT paved the way back in 1996 with a breakthrough by its researcher Dr. Wilhelm Meiners. He laid the cornerstone for the development of laser powder bed fusion (LPBF) – a technique also known as selective laser melting (SLM) – for the production of metal components. LPBF offers enormous advantages compared to conventional manufacturing, not least because it builds components layer for layer, thereby producing a three-dimensional object by means of what is essentially a two-dimensional process.

ILT researchers are looking at the entire physical and digital process chain of LPBF. At present, there are around 90 experts working to advance this technique for use in process engineering, plant technology and industrial applications.

A 3D screen without a 3D headset

Stereoscopic imaging is on the increase in a variety of sectors. These include the entertainment business (3D movies and 3D gaming), industry and manufacturing (production, planning and CAD), and medicine (endoscopy, microsurgery). As a rule, the technology requires users to wear an often cumbersome 3D headset. The alternative is autostereoscopy, also known as glasses-free 3D. Researchers at the Fraunhofer Institute for Telecommunications, Heinrich-Hertz-Institut, HHI have been working in this field since the 1990s and have produced a number of groundbreaking discoveries. Their work covers not only the complex lens systems required for autostereoscopy but also the signal-processing technology needed to present the images in the highest quality.

Today, 3D technology is found in an increasing number of industrial applications. The team from Fraunhofer HHI is focusing increasingly on consultancy services and on the development of specialist solutions, particularly in the medical field.

Adaptronics – the technology for smart structural systems

Structural systems in, for example, vehicles, production machinery and buildings are subject to a variety of stresses. The methods employed to reduce vibrations are fast approaching the limits of technical feasibility and commercial viability. This applies not only to conventional, passive measures but also to active systems based on mechatronics. An alternative approach is known as adaptronics, an innovative interdisciplinary technology to optimize the properties of structural systems. Researchers at the Fraunhofer Institute for Structural Durability and System Reliability LBF have done much to advance this technology over the years. With the help of adaptronics, it is possible to create complex structures that are lightweight and compact while also structurally stable and low on vibration and noise.

This substantially enhances characteristics such as functionality, service life, comfort, safety, and manufacturing efficiency and quality. Moreover, it also reduces weight and operating costs.

Adaptronics has applications in areas such as automobile construction, machine tool design, plant engineering, medical technology, optical systems and aerospace.

The self-sufficient solar house

Completed in 1992, the solar house marked a milestone in the history of the Fraunhofer Institute for Solar Energy Systems ISE. The building’s entire energy requirements are met by means of solar energy. The solar house is equipped with a photovoltaics system, solar panels for heating, transparent thermal insulation, an electrolyzer to convert excess electricity into hydrogen as a medium of energy storage, and a fuel cell to power the stove and provide electricity and warmth in the winter. In addition, the building is constructed in such a way as to draw maximum benefit from the sun’s rays.

In particular, there was an emphasis on systematically integrating all the different technology and components. In this way, the solar house project not only set the tone for many of the institute’s subsequent R&D projects but also anticipated the systematic approach now adopted toward Germany’s so-called energy transition. Fraunhofer ISE continues to investigate the development of building envelopes, building systems and their efficient operation, heating and cooling systems, and thermal storage systems.

ORMOCER® – dental materials with extra bite

Developed at the Fraunhofer Institute for Silicate Research ISC in the early 1990s, the class of materials known as ORMOCER® has proved a high-grade substitute for amalgam. ORMOCER® dental fillings have two key advantages: their biocompatibility and their minimal shrinkage when curing. Furthermore, in external appearance, the material is practically indistinguishable from a real tooth.

There are now numerous ORMOCER®-based dental products on the market. Today, ORMOCER® inorganic-organic hybrid polymers are used for making not only nonallergenic fillings but also dental prostheses. The latter are cheap to produce with industrial extrusion techniques and can be custom-fitted by means of chairside CAD/CAM solutions. In future, it will even be possible to produce dental prostheses with 3D printers. Researchers at Fraunhofer ISC are also investigating biofunctionalized carrier materials based on ORMOCER® polymers. These will enable autonomous regeneration of dental tissue – and usher in a new era in dentistry.

Crystal-clear LCDs

You may very well be using this ingenious technology right now. After all, liquid-crystal displays (LCDs) are to be found in cellphones, laptops, TVs and a host of other electronic devices. In simple terms, liquid crystals alter their polarization when a voltage is applied, which in turn determines how much light they let through. Thanks to a Fraunhofer invention, LCDs remain sharp and distinct no matter the angle from which they are viewed. Researchers at the Fraunhofer Institute for Applied Solid State Physics IAF have been working on LCD technology since the 1970s. And it was they who came up with the technology known as in-plane switching. Günter Baur, then head of department, was awarded the Joseph von Fraunhofer Prize for this groundbreaking development. A patent application was submitted in 1990 and the rights subsequently sold to the company Merck, which continues to supply the world market with liquid crystals for LCDs.