Connecting wind turbines to the public power grid is a huge challenge for manufacturers. It isn’t enough to simply test the functionality of new turbines, connect them and put them into operation — they also have to comply with the limit values for electrical properties specified in the applicable connection rules and compensate for dynamic events such as short circuits and frequency fluctuations. Manufacturers only receive their unit certificate once the full range of tests and certification procedures have been completed. “It has to be done this way because power grids are highly complex systems, and each wind turbine has to help keep them stable,” says Gesa Quistorf, Group Manager Power Electronics and Grid Integration at the Fraunhofer Institute for Wind Energy Systems IWES in Bremerhaven. As turbines are becoming larger in both output and size, however, they are outgrowing the test systems that determine whether a new wind turbine or farm meets the relevant rules. This is particularly true of large offshore wind turbines.

As part of its research project entitled Mobil-Grid-CoP (a name that refers to a mobile test facility for grid compliance tests), Fraunhofer IWES has developed a mobile test bench that is capable of testing even very large wind turbines up to an output of 28 megavolt-amperes (MVA). As a result, manufacturers can obtain their certification much faster than before. The German Federal Ministry for Economic Affairs and Climate Action (BMWK) is funding the project with 12.7 million euros.

A test system that emulates the public grid

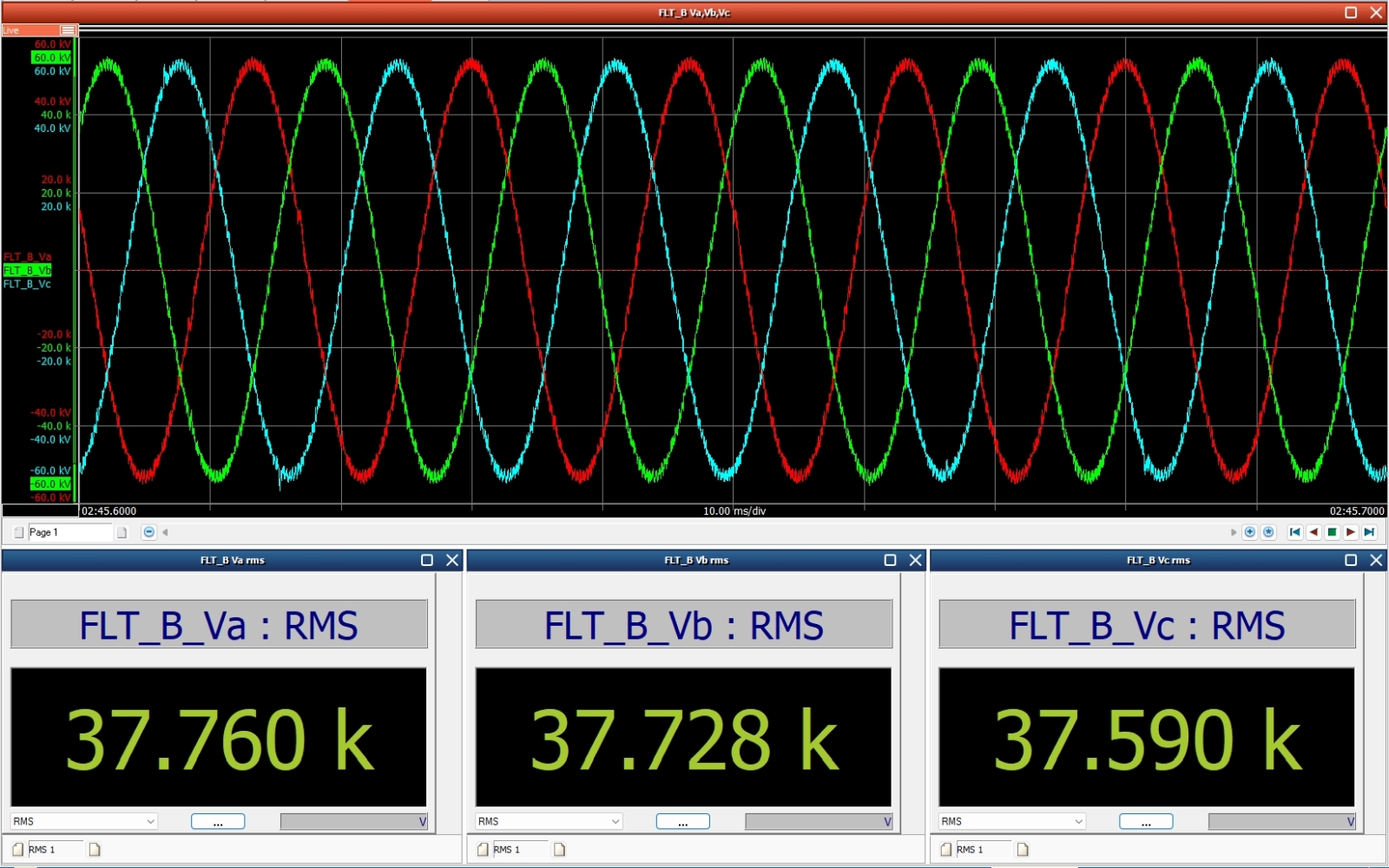

Due to the huge growth in offshore wind farms, the Fraunhofer researchers focused their efforts on large offshore turbines in their development work. The test bench is therefore designed for the typical offshore voltage level of 66 kV, meaning that even large turbines can be tested under realistic conditions at full load. “Our test system is a grid emulator that is switched between the public grid and the test object, simulating the electrical behavior of the power grid to the test object. The public grid is in no way compromised during this process,” explains Quistorf.

During the test, the system examines properties such as the behavior during frequency changes, brief changes in voltage or grid faults such as a short circuit — all in real time. For each event, the wind turbine has to respond within milliseconds. In the event of a short circuit and a subsequent drop in voltage — from 66 kV to 0 kV, for example — the turbine has to support the grid with what is known as reactive current. Unlike active power, reactive power is not usable power that ultimately reaches the consumer; instead, it is needed to build up the voltage in the grid.

A test bench in transportable large containers

The test object only receives its unit certificate and can only be put into operation once it has demonstrated all the required specifications, performance features and capabilities. The test bench is housed in large containers that are transported to the location of the turbine prototypes. In the case of offshore wind turbines, these are generally erected on the coast. The containers include components such as transformers and converters. The Fraunhofer team uses commercially available standard modules for the components, with researchers taking on the task of programming the test and analysis software.

Mobil-Grid-CoP offers a whole host of clear benefits for the wind energy sector. It gives manufacturers the option to carry out robust, realistic and detailed tests on their prototypes to ensure they are ready for certification. This allows them to reduce the risk of having to rework the turbines before putting them into operation and helps them get through the certification and commissioning process faster. The test bench also enables retrospective upgrades or modernization measures to be carried out on a turbine with ease. At Fraunhofer IWES, the mobile test facility can also be combined with other test benches as part of infrastructure expansion measures — all thanks to the facility’s flexible setup.

A test platform for the future

Compared with conventional test systems, the Fraunhofer researchers are going one step further with Mobil-Grid-CoP. “Our aim is to develop a technology platform that facilitates scenario-based, flexible testing of wind turbines. Due to the rapid development in the transition to renewable energy, new connection rules that are unknown as yet could become valid in just a few years. With Mobil-Grid-CoP, we are prepared for this,” explains project manager Quistorf. Through its work, Fraunhofer IWES in Bremerhaven is playing a key role in accelerating the transition of energy grids to renewable sources.