For anyone looking for a high-quality plastic, polycarbonate (PC) is an obvious choice. This material withstands temperature extremes, is flame retardant and resistant to scratching, abrasion, and even diluted acids. It is also highly transparent. All of these properties make plastics that contain PC a sought-after and versatile material in industrial applications. As a result, many manufacturers are looking for ways to reclaim the valuable material by recycling plastic waste. But conventional technologies such as mechanical recycling produce inadequate qualities of recycled material, which can no longer be used to manufacture high-quality products.

Pyrolysis enables chemical recycling

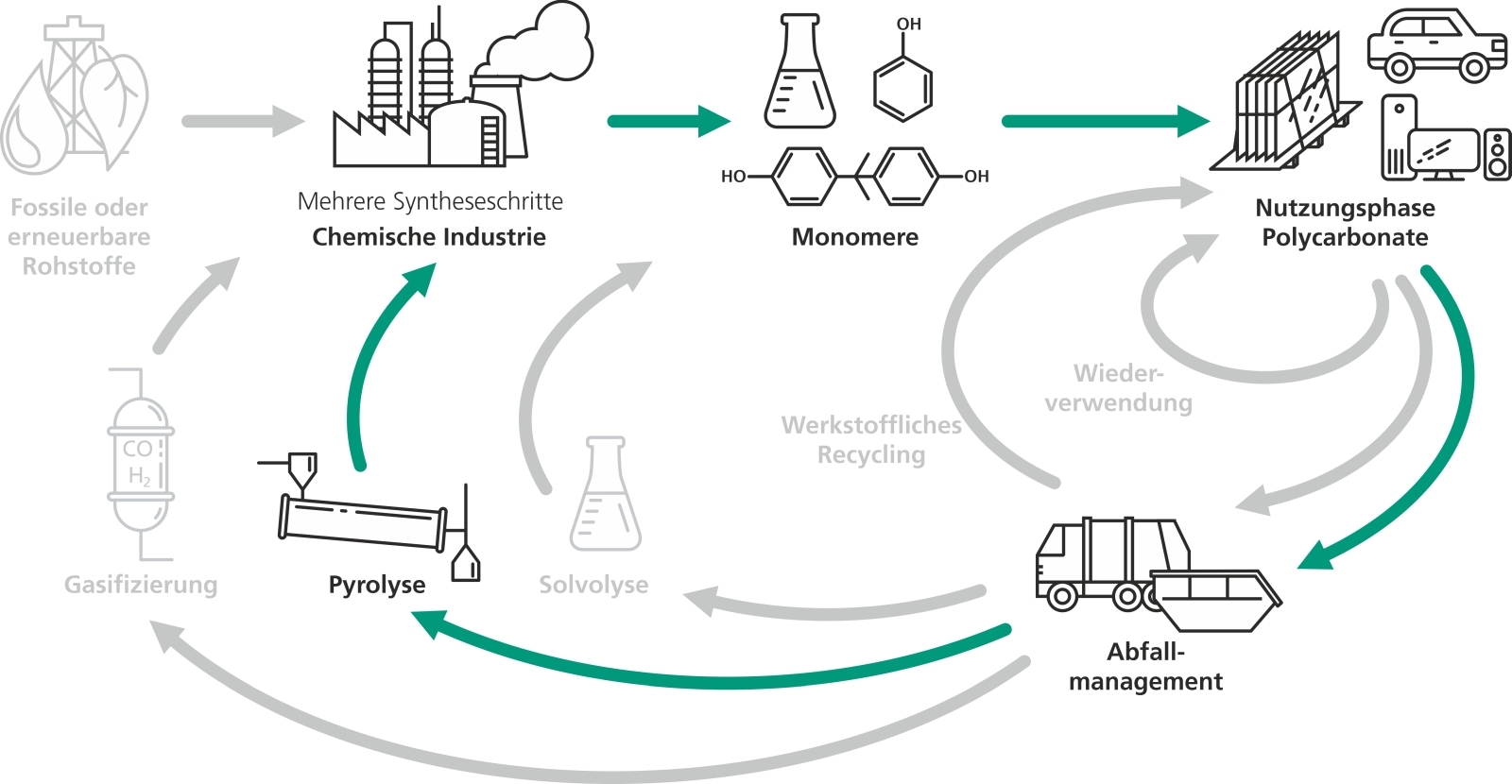

However, there are powerful alternatives. Together with chemical company Covestro Deutschland AG, researchers at the Fraunhofer Institute for Ceramic Technologies and Systems IKTS have developed a method for chemical recycling of polycarbonates through catalytic pyrolysis. In pyrolysis, substances are heated in an environment free of molecular oxygen. As a result, the substances break down, so the components originally used to produce the plastic can be reclaimed.

Jörg Kleeberg, a scientist at the Fraunhofer IKTS office in Freiberg, and his team refined this method as part of the PC2Chem project. “Our goal was to recycle plastics containing polycarbonate in such a way that high-quality molecules can be reclaimed and returned to the industrial production cycle as raw materials,” explains Kleeberg, an expert on carbon cycle technologies.

To do this, the researchers harness the specific structure of polycarbonates. Polycarbonates are made up of polymers, a combination of molecular groups called monomers that are linked together. When these polymers are exposed to thermal stress as part of the pyrolysis process, the bonds with the high-quality molecules simply snap.

Industrial rotary kiln

The Fraunhofer team uses a rotary kiln for pyrolysis. Thanks to its robust structure and size, the kiln can process even relatively large volumes. The plastic waste delivered by Covestro in granulated form is fed into the kiln, which rotates as it heats the material inside it. The first product of the process is gas, which goes into a condensation unit where it ultimately ends up as an oily liquid. Project partner Covestro then processes the liquid into the various useful molecules.

Ensuring that recycling via rotary kiln would result in products with optimum composition and yield presented the team of researchers with a number of hurdles to clear in the lab. Splitting the plastics at high temperature is a highly complex, sensitive process. This meant the big challenge for the Fraunhofer IKTS team was setting the exact parameters for the pyrolysis process: temperature, heating and retention time, cooling, pressure conditions, and the addition of auxiliary and supplemental substances. To make matters worse, the plastics contain additives such as dyes, brighteners, flame retardants, substances that affect strength or elasticity, and even light stabilizers. All of these additives complicate the treatment in the rotary kiln.

“If the products of the reaction caused by pyrolysis in the rotary kiln cool too slowly, the chemical processes aren’t stopped, so the molecules that have been split form new bonds. The only way to get the desired high yield of target products is to set all the parameters correctly in concert with each other. So, we performed extensive testing, optimizing the process step by step,” Jörg Kleeberg explains.

The experts at Fraunhofer IKTS are able to harness their years of experience in the areas of high-temperature conversion and process engineering for this. The PC2Chem project is making good progress. Recycling allows up to 60 percent of the original components to be reclaimed. The system has moved out of the initial lab testing phase and is now being tested at the pilot plant scale.

A step toward the circular economy

The new recycling technology has tangible benefits for industrial applications. The pyrolysis oil extracted in the process contains platform chemicals important to the chemical industry, such as styrene, and phenol. At present, fossil raw materials from refineries still have to be used for these chemicals. Covestro also believes in the advantages of this method: “With the catalytic pyrolysis process, we can reclaim raw materials for polycarbonate production from various forms of waste containing PC. By doing this, we are lowering carbon dioxide emissions, conserving energy, and cutting costs,” explains Dr. Stefanie Eiden, global project manager pyrolysis.

Prof. Martin Gräbner, Head of the Energy and Process Engineering department at Fraunhofer IKTS at the Freiberg location, explains: “The goal isn’t for pyrolysis to replace conventional recycling methods. Instead, it’s a perfect addition when it comes to reclaiming high-quality plastic from plastic residue. The pyrolysis method is a big step toward the circular economy in the industrial sectors that process plastics.”

The team at Fraunhofer IKTS already has its eye on the next step. “We can also adapt the pyrolysis method to other plastics and mixed substances. Industrial customers can come to us with their recycling issues, and we’ll develop a customized solution,” Jörg Kleeberg says.