H2GO – National Action Plan for Fuel Cell Production

Fuel cell electric vehicles (FCEVs) show significant promise as a commercially viable drive system for long-distance transportation in the future. From a technological point of view, fuel cells offer a similar output per volume and weight, and similar ranges and refueling times to conventional fossil-fuel-based drive technologies. This means that haulage companies can retain the flexibility they are accustomed to in their truck operations. Compared to other emission-free drive systems, FCEVs can be economically and ecologically competitive, especially in heavy goods transportation – assuming a successful market ramp-up. Imported hydrogen can reduce the burden on the domestic electricity market, which would otherwise be constrained to produce larger quantities of hydrogen from renewable energies.

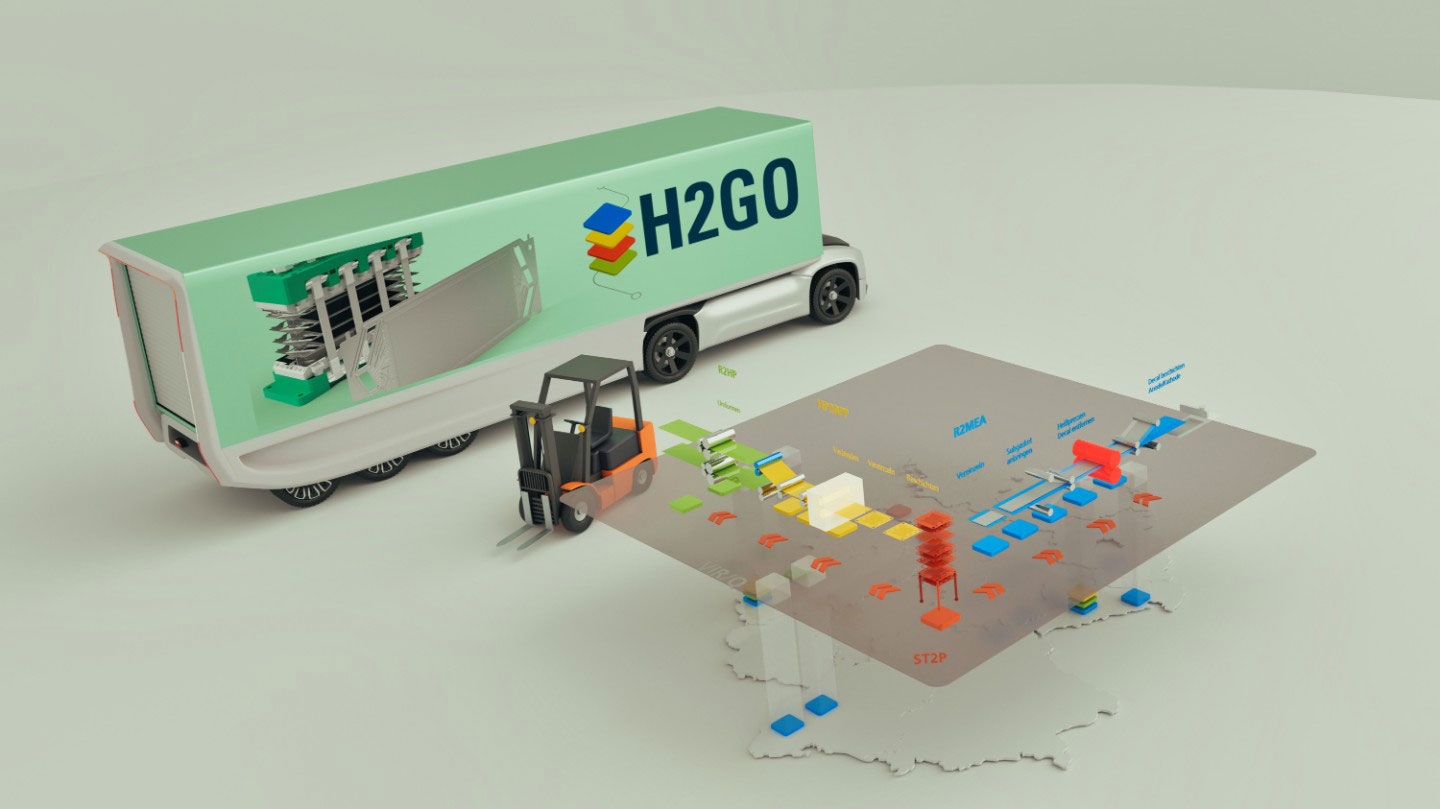

The National Action Plan for Fuel Cell Production H2GO, funded by the Federal Ministry for Digital and Transport (BMDV), supports the establishment of the German fuel cell industry through production technology research, development and industrial implementation. This is intended to ensure national technological sovereignty in the long term, and to enhance the export capability of German truck manufacturers and the necessary mechanical and plant engineering.

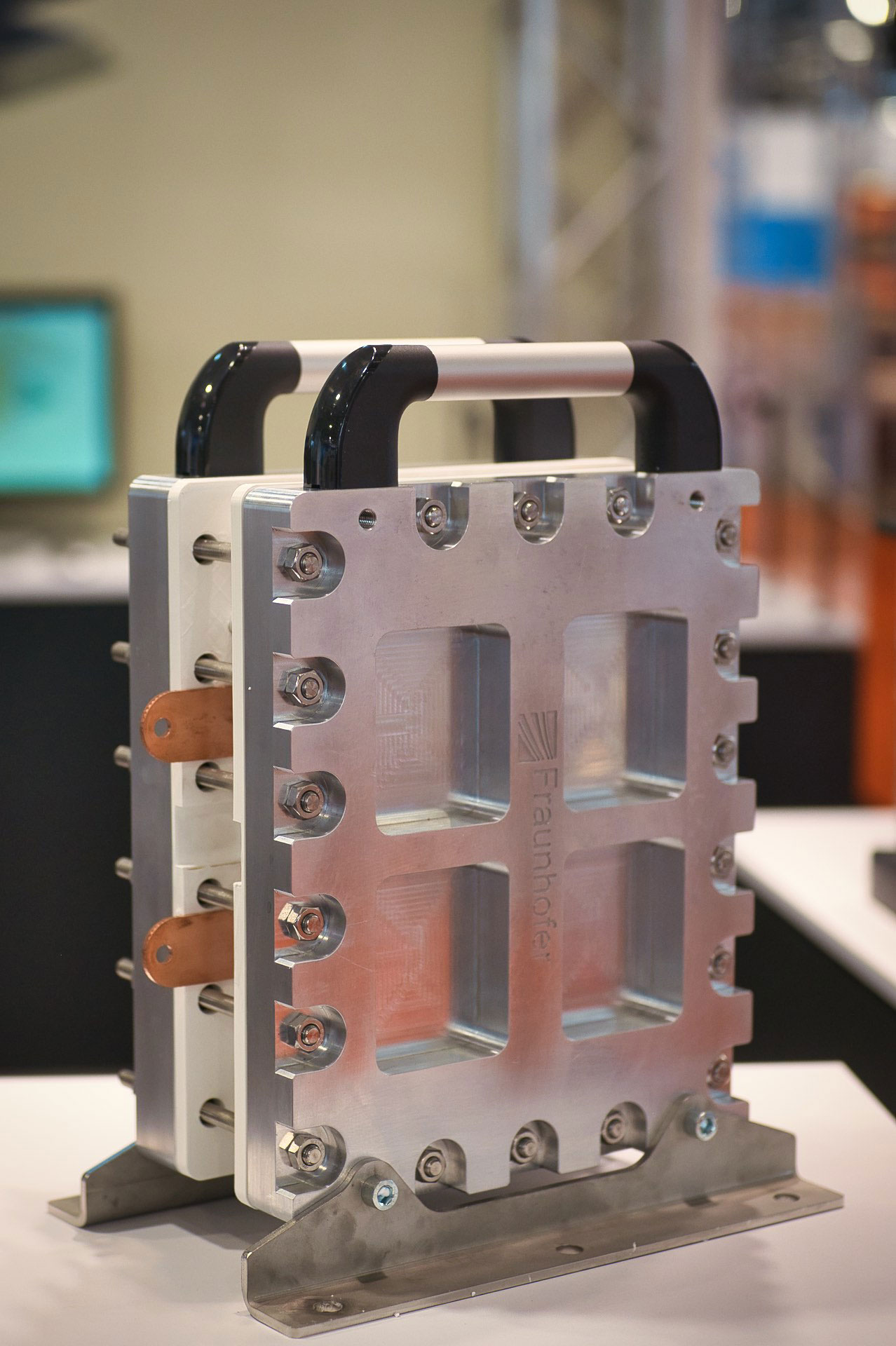

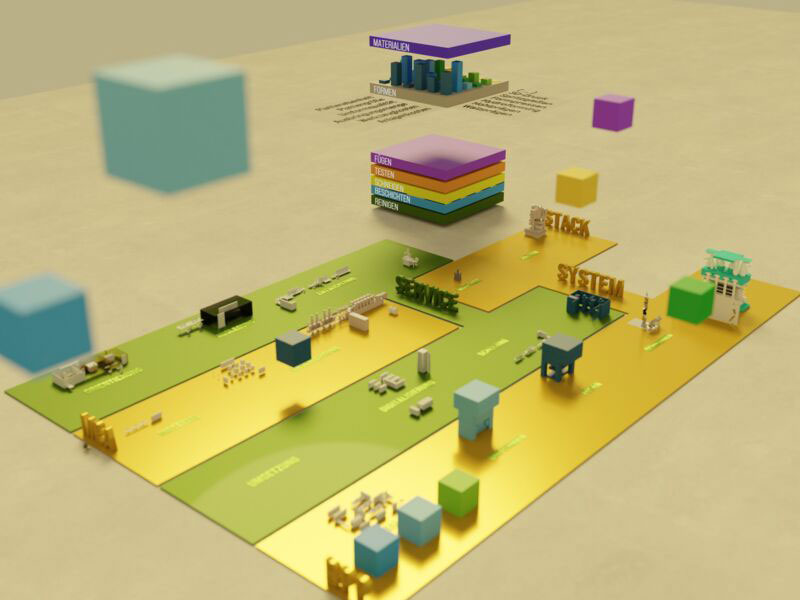

At the heart of this initiative are 19 Fraunhofer institutes based in 9 federal states which, in collaboration with their local networks, draw on their research expertise and infrastructures to develop new manufacturing solutions within regional technology hubs. These will be integrated into the four technology alliances for proton exchange membranes (R2MEA), bipolar plates (R2HP, HP2BPP) and industrial dismantling and transfer to recycling and reuse (ST2P), and enhanced through targeted state and federal initiatives. The overarching NEXUS network: ViR enables synergetic integration in a virtual reference architecture for fuel cell production based on the digital images of the developed production solutions.

Due to its advanced technical maturity, the high-rate process chain gives new, previously uninvolved industries the opportunity to expand their business field through fuel cell production. Besides component manufacturers and system integrators, the mechanical and plant engineering sector therefore also benefits from the innovative production solutions resulting from the National Action Plan. The H2GO developments also offer new economic prospects for other companies with specialized processes, as well as moldmakers, material suppliers, engineering, measurement and control technology. The approach is neutral and independent of specific companies. In particular, the concept of the Action Plan makes it possible to explore innovative future production concepts that are pre-competitive and go far beyond the technologies currently available. The Action Plan promotes comprehensive knowledge and technology transfer, and also makes the newly created infrastructure available to various industrial partners for direct cooperation, sampling, pilot production or spin-offs, and for the further development of both production processes and fuel cells as a product. Rather than merely subsidizing individual consortia, this enhances the entire value-creation ecosystem.