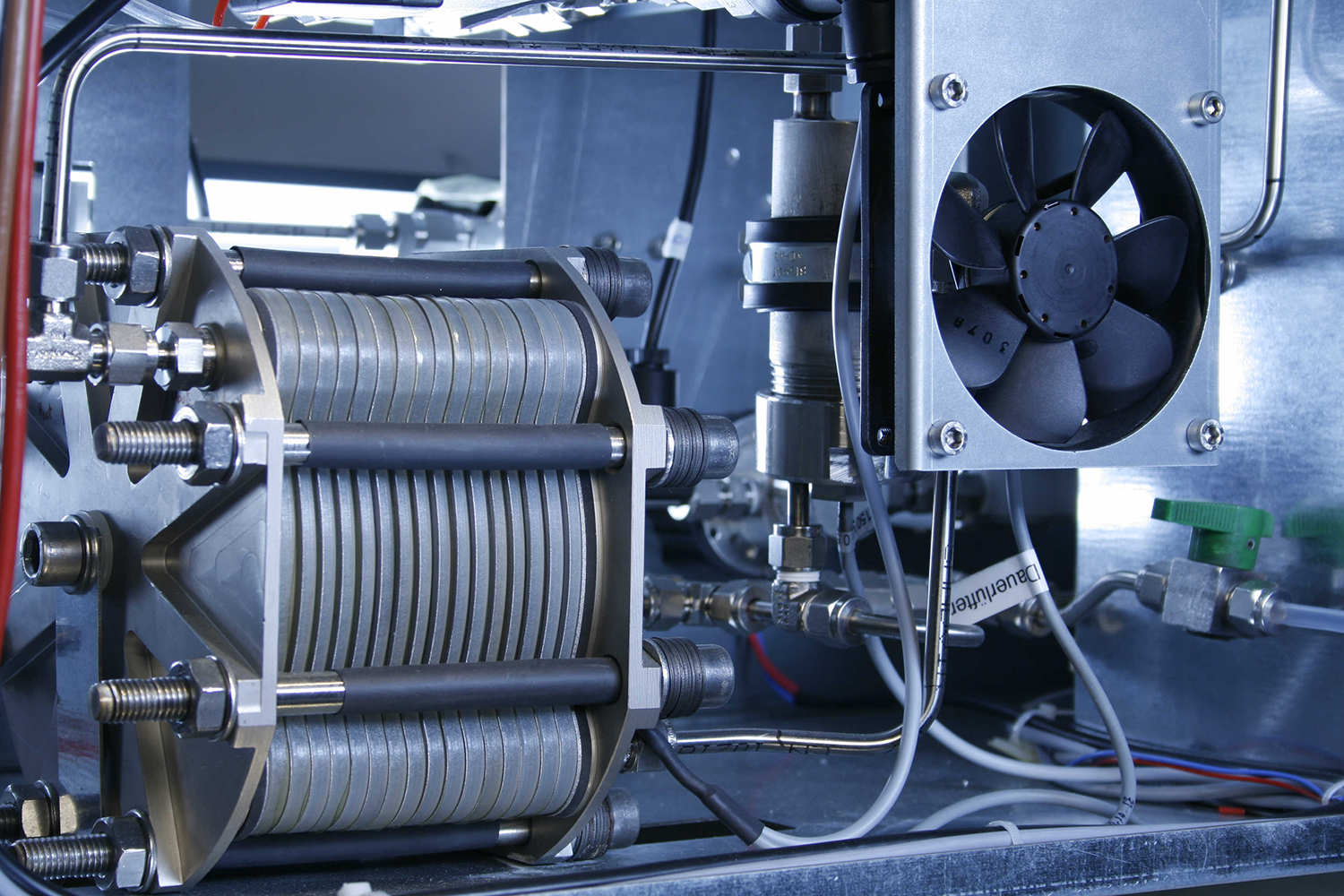

An alternative route to a more compact electrolyzer and cost-effective catalyst material is via the use of alkaline electrolysis cells. With the basic processes well understood, the focus is now on questions of application. In the REVAL project, Fraunhofer IFAM and Fraunhofer IMWS are working with partners from industry to improve the long-term stability of the electrodes. This project forms part of the BMBF-funded inititiave Hydrogen Power Storage & Solutions East Germany (HYPOS). Its purpose is to develop an efficient prototype that remains stable during long-term operation and to take this to the production stage.

High-temperature electrolysis is conducted at temperatures above 800°C. Wherever waste heat is available, this can be used to accelerate a reaction without the need for a catalyst such as a noble metal. Moreover, the same system components can be used both as an electrolyzer and as a fuel cell. Finally, this type of electrolysis can also be used for the co-electrolysis of water into H2 and O2, and of CO2 into oxygen and carbon monoxide (CO). Together, CO and H2 form synthesis gas, the basis for the production of numerous chemical products. Fraunhofer IKTS is investigating the long-term stability of the high-temperature electrolyzer as well as its efficiency and costs.

Teams are busy optimizing materials, building cells and then constructing stacks from these cells. These stacks undergo material testing or are incorporated within larger systems. Fraunhofer IKTS has built a 1-kilowatt pilot plant that combines high-temperature electrolysis with the Fischer-Tropsch synthesis. In the Colyssy project, which forms part of the HYPOS initiative, researchers are now upscaling this pilot plant to 10 kilowatts for use in industry (see “Climate-neutral industrial processes,” p. 7).

Fuel cells: converting hydrogen back to electricity

Fuel cells convert the energy stored in hydrogen back into electrical energy via a controlled process. For stationary applications, the preferred choice of technology includes the solid oxide fuel cell (SOFC). This is suitable, in particular, for generating combined heat, power and, optionally, cooling; and it can be run on hydrocarbons as well as pure hydrogen. Fraunhofer IKTS has developed an SOFC system that generates power and heat extremely efficiently – for use in, for example, remote areas with no grid connection. Fraunhofer IKTS is also working on planar cells and stacks. This technology is being developed for market in cooperation with various partners, including the Dresden company Sunfire.

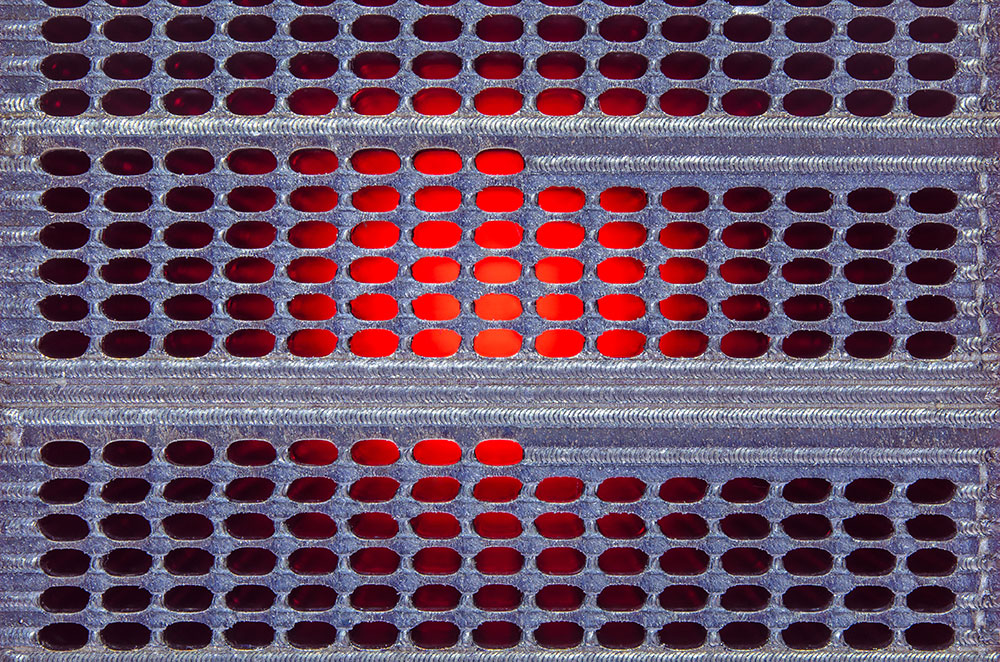

For vehicles, the most suitable form of this technology is the PEM fuel cell, which has a high power density and delivers an extremely dynamic performance. In this instance, the membrane coating forms the electrodes. This is also known as a membrane electrode assembly (MEA). In the HyFab project, which is funded by the state of Baden-Württemberg, Fraunhofer ISE is investigating the functional relationships in the catalyst layer and enhancing the process technologies required for a mass production of MEAs.

In order for the fuel cell stack to function properly, it must remain perfectly sealed. Together with Chemnitz University of Technology and partners from industry, Fraunhofer IWU has been working on smart seals that can detect any changes in the prestressing of the stack during operation. Shape-memory alloys are to used to restore optimal prestress loads.

Reforming systems

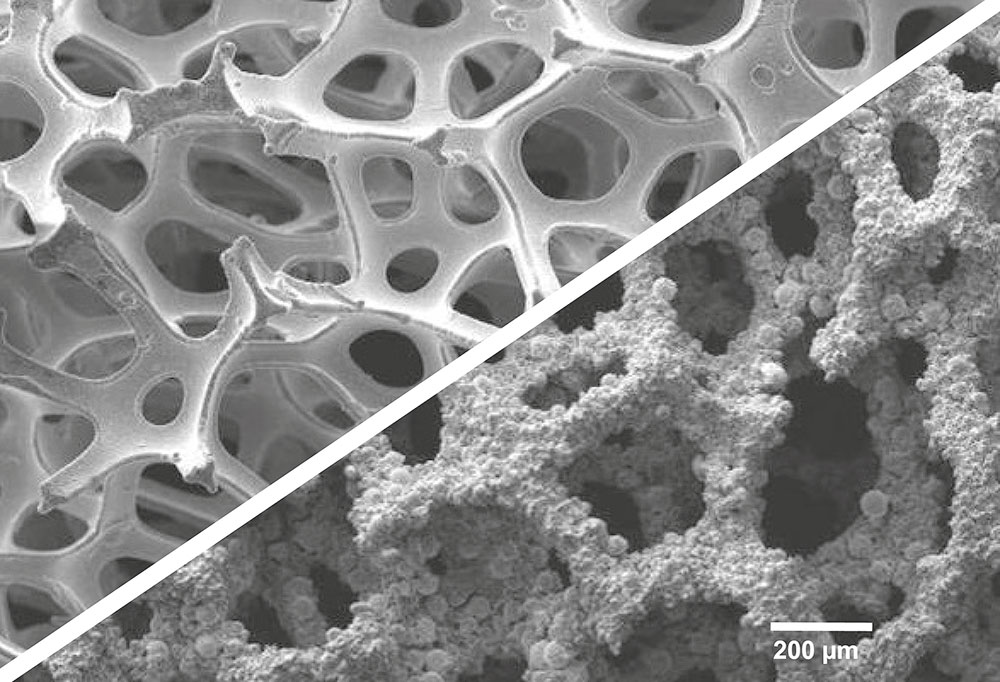

At present, most hydrogen is produced by reforming organic compounds – in the simplest case, methane or methanol – rather than by electrolyzing water. This method of hydrogen production can also play a role in a sustainable industry, provided that the organic compounds come from biomass and that the carbon monoxide produced in the process is removed from the global cycle. A number of Fraunhofer Institutes are working to enhance the various reforming processes used for this purpose. Fraunhofer IMM develops complete solutions for fuel processing and synthesis on the lab, pilot and industrial scale. Fraunhofer IKTS is focusing on the burner and, in particular, ceramic foams, which are the heart of this component. To deliver a long service life, these ceramic foams have to be extremely resistant to high temperatures and thermal shocks. Open-celled ceramic foams made of silicon carbide are especially suitable for this purpose. Researchers tailor these ceramic foams according to the requirements of the specific type of burner or reformer and enhance them accordingly. Specialty ceramic foams developed by Fraunhofer IKTS display exceptional strength at temperatures as high as 1300°C.

Catalysts – a key part of the process

To build an efficient electrolyzer or fuel cell, it is vital to have a high-performance, cost-effective catalyst. A number of Fraunhofer Institutes have built up major expertise in this field. Their target is to reduce the use of noble metals while also increasing catalyst efficiency. In an electrolyzer, the hydrogen electrode has completely different specifications to the oxygen electrode. In the HyCOn project, which is funded by the BMBF, researchers from Fraunhofer ICT have come up with supported catalysts based on iridium oxide for the production of oxygen. They are also investigating increases in activity through the formation of mixed oxides and the occurrence of defects as a result of halide doping. Building on this preliminary work, Fraunhofer ICT is working on bifunctional oxygen catalysts for PEM-based unitized regenerative fuel cells. Fraunhofer ICT is also developing electrocatalysts for various types of electrochemical cells in the low- and mid-temperature ranges (to around 200°C). Here, researchers are working to enhance the electrodes used in the high-temperature PEM fuel cell. Meanwhile, in a project on behalf of the German Federal Ministry of Defence (BMVg), Fraunhofer ICT is developing materials and systems for this type of fuel cell that are suitable for operation with so-called logistic fuels. New catalysts for water and CO2 electrolysis are also under development at Fraunhofer UMSICHT.

Storage methods

Different applications for hydrogen demand different concepts for the storage and transport of this coveted gas. For transport of less than 100 kilometers, Fraunhofer IFF has developed a portable, modular hydrogen storage tank that weighs less than 750 kilograms and can be loaded onto a (green) pickup truck. Hydrogen can also be stored in the form of liquid organic hydrogen carriers (LOHCs). For this purpose, a transfer oil is hydrogenated, thereby obviating the need for pressurized tanks or cooling systems. Researchers at Fraunhofer IAO have built Europe’s first LOHC storage system of the latest generation, with a capacity of 2000 kilowatt-hours. As an alternative, Fraunhofer IFAM in Dresden is developing an easy-to-handle “Powerpaste,” which stores hydrogen in a chemical form at room temperature and atmospheric pressure. Hydrogen is released simply through the addition of water.