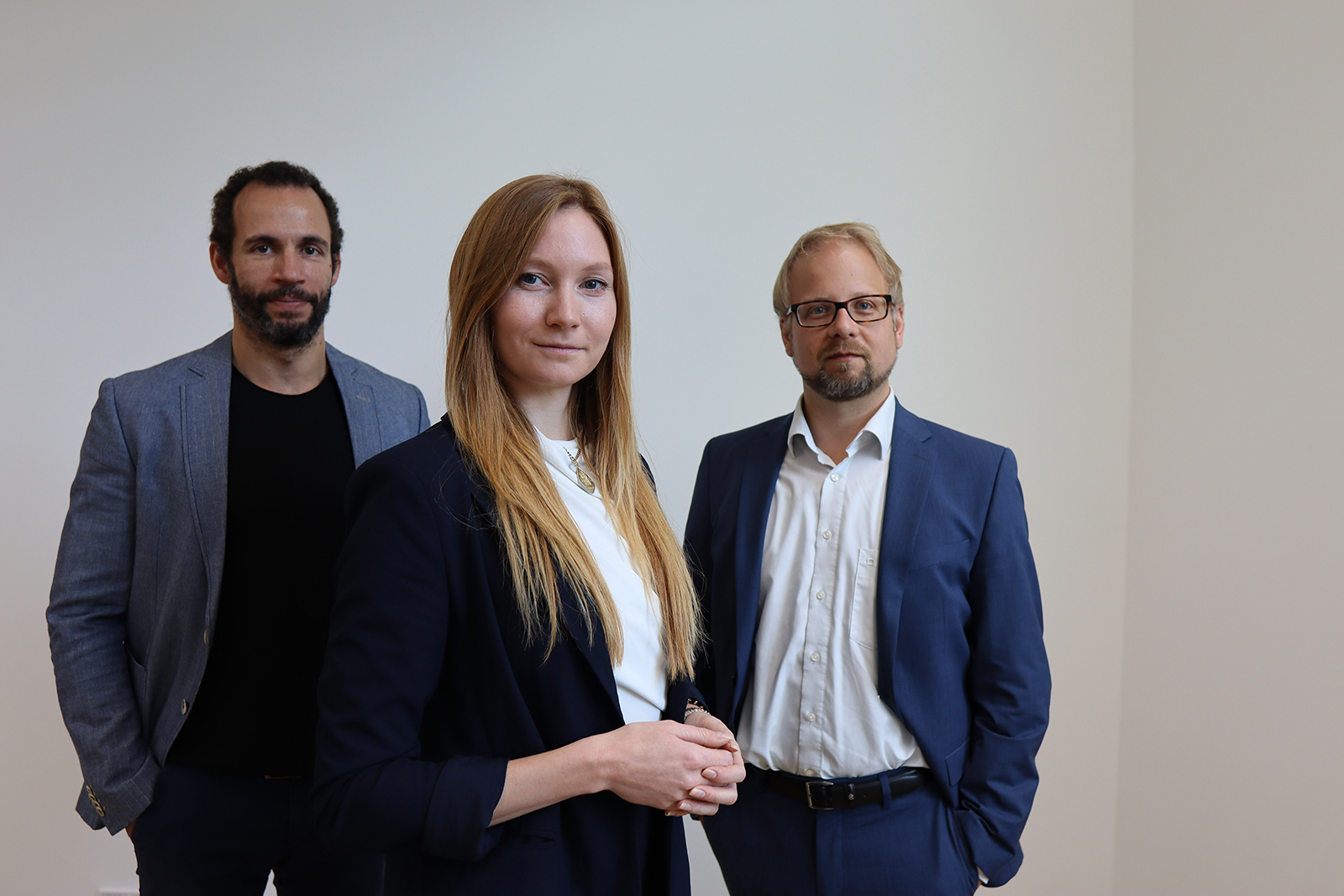

There are various methods that have the potential for minimizing or even eliminating animal testing. These methods include human stem cells that are grown in vitro and used to form miniature organs known as organoids. Researchers at Fraunhofer ISC/TLC-RT in Würzburg are also working to develop these kinds of in-vitro tissue models with various areas of focus, including barrier organs like the skin. These lab-grown cell aggregates can be used to trace physiological processes and study them under controlled conditions — one way to replace or reduce animal testing. The researchers involved in the TigerShark Science start-up project are taking the same approach: They have succeeded in culturing a skin model that can represent almost all of the structures present in human skin, making it a realistic skin model. With their start-up idea, which received funding from Fraunhofer’s AHEAD program and will be funded through EXIST Transfer of Research starting in July 2024, the team of researchers is now approaching the official spin-off stage. The founding team includes Dr. Florian Groeber-Becker, head of Fraunhofer TLC-RT at Fraunhofer ISC, Dr. Dieter Groneberg, group manager for in-vitro skin testing systems at the Fraunhofer TLC-RT, and Amelie Reigl, a project manager at the Fraunhofer TLC-RT and future managing director of TigerShark Science.

Complex models with three layers of skin

The start-up plans to begin by offering the pharmaceutical and cosmetics industries large unit volumes of healthy skin models simulating three layers of the skin — the epidermis, dermis, and hypodermis — with fat cells. These models are suitable for applications such as testing medications and their side effects or studying hair growth. The organoids are complex skin models comprising various cell types. Like human skin, they have sebaceous glands and hairs. They can be used to study aspects such as how cells communicate with each other after an active ingredient is administered and whether active ingredients trigger irritation. “There have been no skin models of this complexity on the market to date. They’re one of a kind,” Reigl says, explaining the technology’s unique selling proposition and great potential.

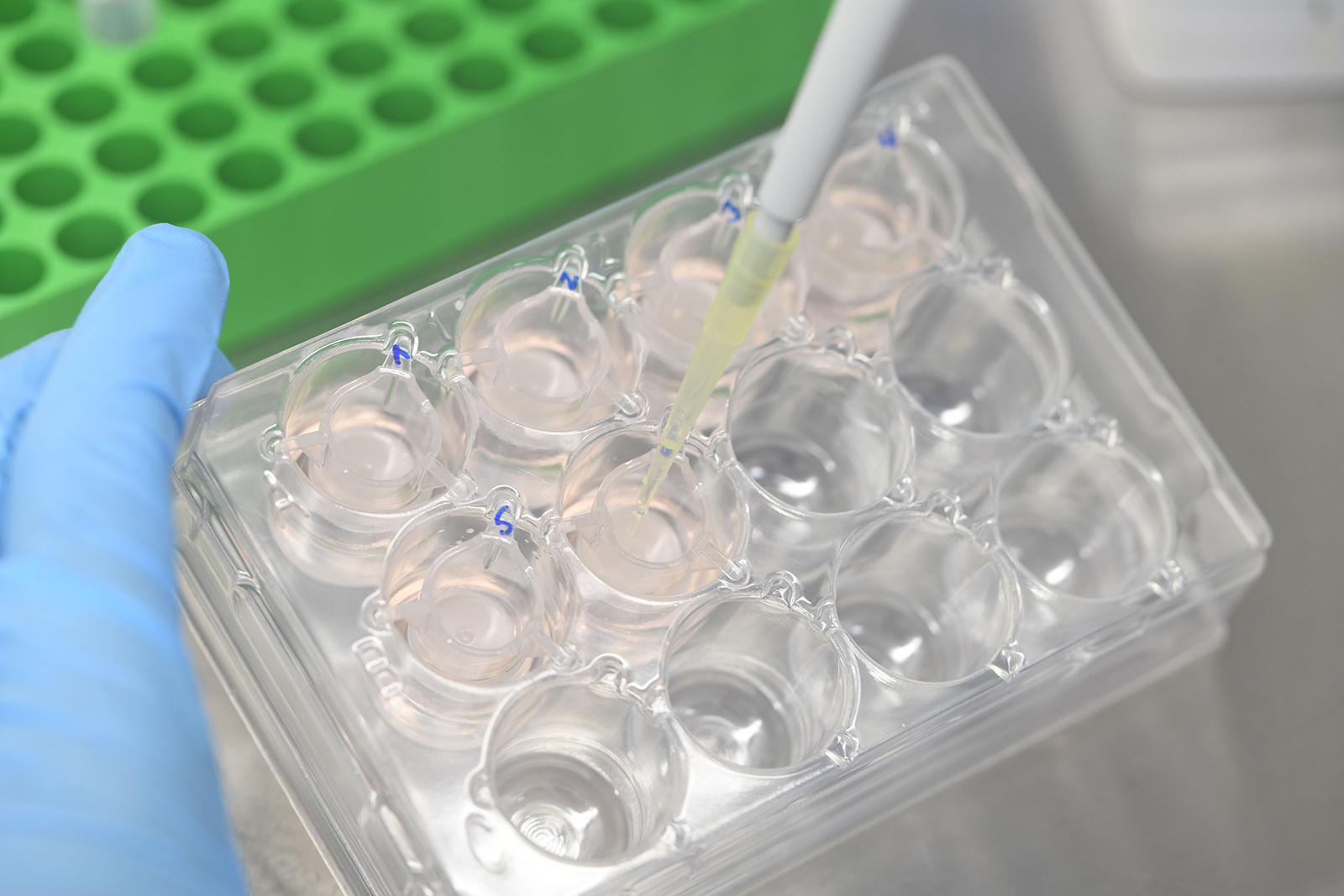

Organoids can be cultured in open air

An automated process is used to develop the organoids in large numbers inside a bioreactor. They are then applied to nanofibers using a special method. This creates what is known as an air–medium interface culture, in which the uppermost layer of the skin, the epidermis, is in contact with the air — unlike when the tissue is cultured in a Petri dish. The nanofibers are already patented, and there are also plans to patent the method itself.

Skin models for preclinical testing

The model enables fast testing, a huge advantage over animal tests, which can often be expensive and time-consuming. The skin organoid made from human stem cells can be used to achieve faster, more accurate results, in many cases with greater applicability in humans. It takes just one step to study the reactions of cells in all three layers of the skin, an option that has not been available on the market to date.

Broad product portfolio of various skin models planned

The skin model is currently undergoing further development. Future plans call for adding models with immune cells and blood vessels, and even models with tumor cells, which can be used to simulate and study diseases and conditions such as skin cancer. With the growing complexity of the model, further fields of application such as aspects of wound healing can be addressed or infection studies carried out. “We plan to grow our portfolio in stages. As the first step, we’re bringing the healthy skin model to market, but there will be others as well, such as a skin model to study skin fibrosis,” Reigl explains.