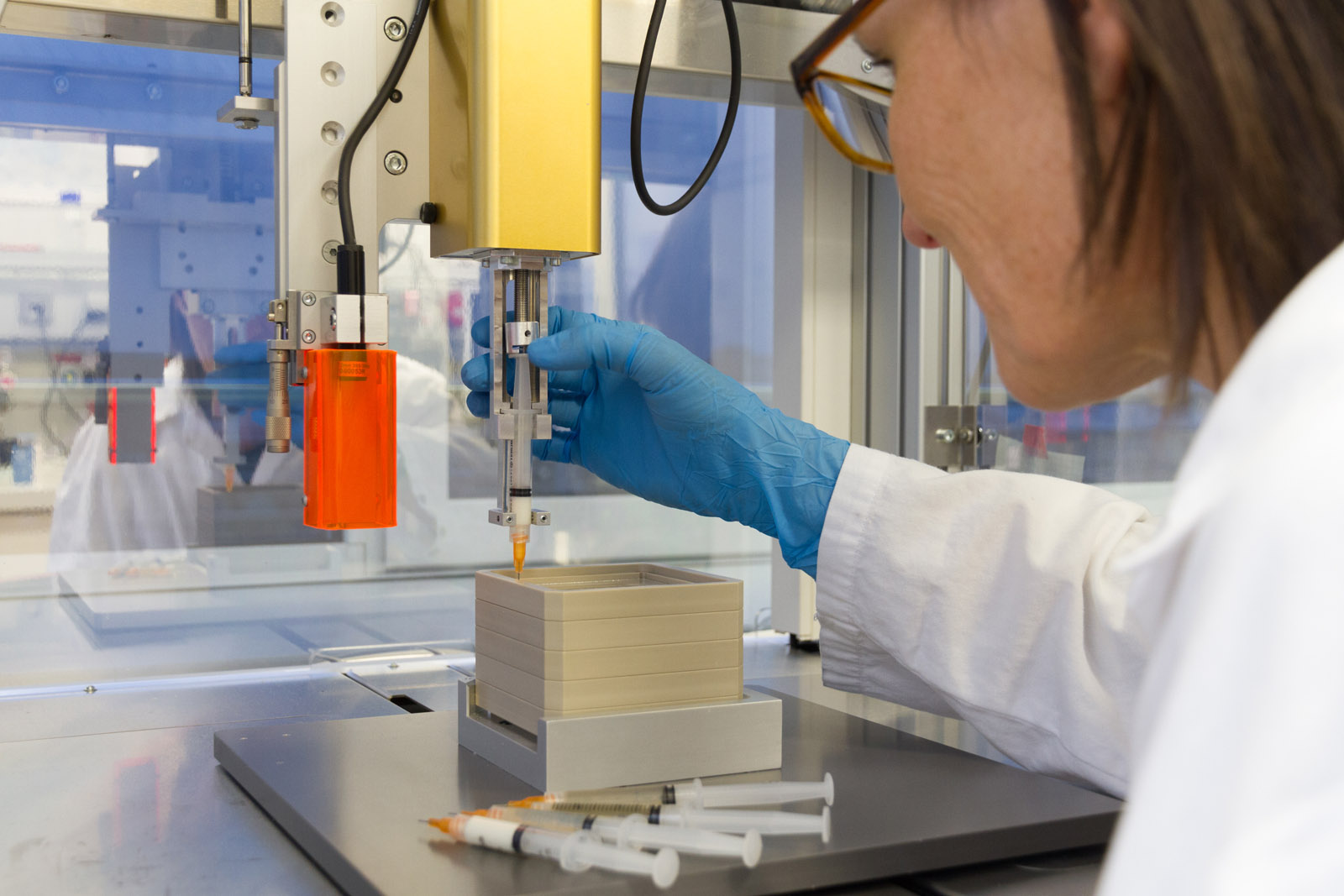

3D printing is not only gaining ground in manufacturing – it is also taking on increasing importance in the realm of regenerative medicine. Scientists are now hoping to use this additive manufacturing method to create bespoke biocompatible tissue scaffolds that will replace irreparably damaged tissue. A team of researchers at Fraunhofer IGB in Stuttgart is also working on biobased inks for manufacturing biological implants in the laboratory using 3D printing techniques. To create a 3D object in the desired pre-programmed shape, the team utilizes a layer-by-layer approach to print a liquid mixture comprising biopolymers such as gelatin or hyaluronic acid, aqueous medium and living cells. These bio-inks remain in a viscous state during printing and are then exposed to UV light to crosslink them into water-containing polymer networks called hydrogels.

Targeted chemical modification of biomolecules

Scientists can chemically modify the biomolecules to provide the resulting gels with different degrees of crosslinking and swellability. This makes it possible to imitate the consistency of natural tissue – from stronger hydrogels for cartilage to softer gels for fatty tissue. Broad adjustments can also be made to the level of viscosity: “At room temperature of 21 degrees Celsius, gelatin is as firm as jelly, which is no good for printing. To prevent temperature-dependant gelation and to enable us to process it regardless of temperature, we ‘mask’ the side chains of the biomolecules that are responsible for gelling gelatin,” says Dr. Achim Weber, head of the Particle-Based Systems and Formulations Group, explaining one of the key challenges encountered in the process.

A further challenge is that the gelatin must be chemically crosslinked to prevent it from liquefying at temperatures of around 37 degrees. To achieve this, it is functionalized twice: in this case, the research team has opted for integration of crosslinkable methacryl-groups into the biomolecules thereby substituting various parts of the non-crosslinking, masking acetyl groups – a unique approach in the field of bioprinting. “We formulate inks that offer adjusted conditions for different cell types and tissue structures,” says Dr. Kirsten Borchers, who is responsible for bioprinting projects in Stuttgart.

In collaboration with the University of Stuttgart, the team recently succeeded in creating two different hydrogel environments: stiffer gels with mineral components to cater to bone cells, and softer gels without mineral components to enable blood vessel cells to form themselves into capillary-like structures.

Bone and vascularization inks

The researchers have already succeeded in producing bone ink on the basis of the material kit they created. Their goal is to enable the cells processed in the kit to regenerate the original tissue, in other words to form bone tissue themselves. The secret to creating the ink lies in a special mixture of the bone mineral powder hydroxylapatite and biomolecules. “The best artificial environment for the cells is one that comes closest to the natural conditions in the body. That’s why the role of the tissue matrix in our printed tissues is played by biomaterials that we generate from elements of the natural tissue matrix,” says the scientist.

The vascularization ink forms soft gels that support the establishment of capillary structures. Cells that form blood vessels are incorporated in the inks. The cells move, migrate toward each other and form systems of capillary networks consisting of small tubular structures. If this bone substitute was to be implanted, the biological implant would connect to the recipient’s blood vessel system much faster than an implant without capillary-like pre-structures, as detailed in the relevant literature. “It would probably be impossible to 3D-print larger tissue structures successfully without vascularization ink,” says Weber.

The Stuttgart team’s latest research project involves developing matrices to regenerate cartilage. “Whatever type of cell we isolate from body tissue and multiply in the laboratory, we have to create a suitable environment in which they can fulfil their specific functions over longer periods of time,” explains the team’s bioengineer, Lisa Rebers.

Fraunhofer IGB is continuing to pursue its research work in the Mass Personalization High-Performance Center in Stuttgart as part of a joint initiative with the Fraunhofer Institute for Manufacturing Engineering and Automation IPA and the University of Stuttgart. The Additive4Life interdisciplinary working group is responsible for creating new technologies and printable biomaterials for bioprinting.